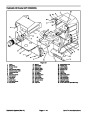

Traction Pump Assembly

11

1.

Make sure all parts are cleaned thoroughly and free

of dirt and debris.

8

3

9

2

2.

Secure ball bearing onto shaft with retaining ring.

5

Press assembly into variable housing. Snap retaining

ring into housing to secure bearing and shaft (Fig. 49).

6

4

7

1

10

IMPORTANT: Make sure not to damage the face sur-

face on the cavity side of the variable housing.

3.

Position variable housing so the large cavity is up.

Press needle bearings into each side of the variable

housing. Make sure bearings are flush to 1/64 inch (0.40

mm) below the counter bore for the lip seals (Fig. 49).

Figure 49

1.

Variable housing

Spring pins

Control shaft

Trunnion shaft

Swashplate

Shaft

7.

8.

9.

10. Needle bearing

11. Journal bearing

Retaining ring

Ball bearing

2.

3.

4.

Retaining ring

4.

Place swashplate into variable housing with the

5

.

counter bore for the thrust plate facing up (Fig. 49).

6.

5.

Make sure control shaft is positioned to the proper

side of the variable housing before installing. The con-

trol shaft should be installed on the side of the pump that

will accept the pump control linkage (Fig. 49).

2

4

3

1/4

INCH (6.4 mm)

A. Insert control and trunnion shafts through the

housing into the swash plate bores.

B. Make sure holes in the swashplate and shafts

are aligned properly.

1

6.

into the control and trunnion shafts (Fig. 50).

Insert new spring pins through the swashplate and

7

1

6

5

A. Install first pin until the second pin can be

started.

Figure 50

1

.

Spring pin

5.

6.

7.

Variable housing

Needle bearing

Journal bearing

B. Drive both pins in until the last pin is 1/4 inch

2.

3.

4.

Swashplate

Control shaft

Trunnion shaft

(6.35

mm) below the swash plate.

C. Repeat steps A and B on the other shaft.

D. Make sure swashplate swings freely and to 15o

each way from the center position.

2

7.

Lubricate thrust plate with clean hydraulic fluid.

5

Make sure contact surface for the piston shoes is facing

up (Fig. 51).

NOTE: Piston placement in the bores requires no spe-

1

cial orientating.

3

4

8.

Lubricate cylinder block, spider, and piston assem-

blies with clean hydraulic oil. Insert piston assemblies

through the spider and into the bores. Make sure spider

and spider pivot contact surfaces align properly (Fig.

51).

6

Figure 51

1.

2.

3.

Cylinder block

Cylinder block assembly

Spider

4.

5.

6.

Piston assemblies

Thrust plate

Variable housing

Hydraulic System (Rev. A)

Page 4 – 54

Sand Pro 2020/3020/5020

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro 3020, Toro 5020, Toro 98957SL.Toro 2020 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)