7.

to the hydrostat while pulling the pump plate from the hy-

drostat (Fig. 32).

Remove three cap screws securing the pump plate

6. Remove caps and plugs from disconnected hoses

and fittings.

7.

Reinstall hydraulic hoses (11 and 14) to 90o hydrau-

lic fittings (13 and 12).

8.

Clean all hydraulic fittings and hydraulic hoses at-

tached to the hydrostat. Label all hydraulic connections

for reassembly.

8.

push on fitting (10). Tighten hose clamp.

Reinstall hose clamp (30) and suction hose (8) to

9.

hydraulic oil.

Place a suitable container under hydrostat to collect

9.

lic tank from suction hose (8).

Remove clamp used to prevent draining the hydrau-

10.

draulic tank.

Clamp suction hose (8) to prevent draining the hy-

10.

to hydrostat (9).

Reinstall hydraulic hoses (4 and 5) and O–rings (29)

11.

draulic fittings (13 and 12). Allow fluid to drain from the

hoses into the container.

Remove hydraulic hoses (11 and 14) from 90o hy-

11.

screws. Tighten cap screws while attaching the pump

plate to the hydrostat (Fig. 32).

Secure pump plate to the hydrostat with three cap

12.

Allow fluid to drain from the hose into the container.

Remove suction hose (8) from push on fitting (10).

12.

pump lever to the hydrostat trunnion with cap screw and

lock nut (Fig. 32).

Align pump lever to the hydrostat trunnion. Secure

13.

Remove hydraulic hoses (4 and 5) and O–rings (29)

from the hydrostat. Allow fluid to drain from the hoses

into the container.

13.

Reconnect wires to the neutral switch (Fig. 32).

14.

control rod to the pump lever with flat washer and cotter

pin (Fig. 32).

Insert control rod into the pump lever. Secure pump

14.

tings to prevent contamination.

Put caps or plugs on disconnected hoses and fit-

15.

16.

moval. Remove both hex nuts (27), lock washers (28),

cap screws (6) from the hydrostat (9) and pump mount

Loosen both set screws (20) from hydrostat shaft.

Support hydrostat to prevent dropping during re-

15.

Secure muffler shield to the engine with three cap

screws and lock star washers securing. Make sure R–

clamp and fuel hose a secured to the muffler shield by

cap screw and lock star washer.

(25).

Pull hydrostat from mount and machine.

16.

Secure cover to the midsection of the machine and

17.

Remove woodruff key (26) from hydrostat shaft.

pivot seat down.

18.

Match mark position of hydraulic fittings on the hy-

17. Charge hydraulic system (see Charge Hydraulic

System).

drostat. Remove remaining fittings (10, 12, and 13) and

O–rings (31 and 32) from the hydrostat. insert caps or

plugs into open ports of the hydrostat.

4

Installation (Fig. 31)

3

1.

tubes are cleaned thoroughly.

Make sure lift valve, hydraulic hoses, fittings, and

5

2.

13)

Reinstall O–rings (32) and hydraulic fittings (12 and

to the hydrostat. Observe match marks when tight-

2

ening.

1

3.

Remove caps or plugs from the hydrostat.

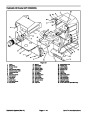

Figure 32

1.

2.

3.

Control rod

Pump lever

Wires

4.

5.

Neutral switch

Pump plate

4.

Install woodruff key (26) to hydrostat shaft. Support

hydrostat (9) while positioning onto pump mount (25).

Make sure woodruff key (26) stays in place when the

shaft is inserted into the pump hub (24).

5.

Secure hydrostat to mount with both cap screws (6),

lock washers (28), hex nuts (27). Tighten set screw (20)

to hydrostat shaft.

Sand Pro 2020/3020/5020

Page 4 – 43

Hydraulic System (Rev. A)

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro 3020, Toro 5020, Toro 98957SL.Toro 2020 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)