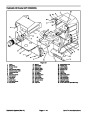

Removal (Fig. 57 or 58)

Before removing any parts from the hydraulic sys-

tem, park the machine on a level surface, lower attach-

ment, and stop the engine.

10. Remove hydraulic fittings and O–rings from the

wheel motor. Put caps or plugs on disconnected tubes

and motor ports to prevent contamination from entering.

1.

11. Remove hex cap screws, spacers, and lock wash-

ers securing the brake bracket and wheel motor to the

frame. Remove motor from the frame.

CAUTION

Installation (Fig. 57 or 59)

1.

and brake bracket to the frame with four cap screws,

spacers, and lock washers.

Position wheel motor to the frame. Secure motor

Operate all hydraulic controls to relieve system

pressure and avoid injury from pressurized hy-

draulic oil. Controls must be operated with the

ignition switch in OFF. Remove key from the igni-

tion switch.

2. Remove caps or plugs from the wheel motor. Lubri-

cate new O–rings with clean hydraulic fluid. Install O–

rings and hydraulic fittings to the motor and tighten.

WARNING

NOTE: The right wheel motor has an extra hydraulic

tube and fitting attached to it.

Before jacking up the machine, review and follow

Jacking Instructions in Chapter 1 – Safety.

3. Lubricate new O–rings with clean hydraulic fluid.

Install O–rings and hydraulic tubes to the hydraulic fit-

tings. Tighten tube connections.

2.

Jack up rear wheel and use wood blocks to keep the

rear tire off the floor.

NOTE: The brake assembly consists of return spring,

brake cam, brake shoes, backing plate, and retaining

clip.

3.

Remove lug nuts from drive studs. Pull wheel from

drive studs and wheel hub.

4.

Install brake assembly to the brake bracket by se-

IMPORTANT: DO NOT hit wheel hub with a hammer

during removal. Hammering may cause damage to

the motor.

curing the backing plate to the brake bracket with four

cap screws and lock nuts. Secure brake lever to the

brake cam with the retaining clip.

4.

motor shaft. Release parking brake.

Apply parking brake. Remove lock nut from wheel

IMPORTANT: DO NOT hit wheel hub with a hammer

during installation. Hammering may cause damage

to the motor.

5.

Use a puller to remove brake drum and wheel hub.

Remove woodruff key from the wheel motor shaft.

5.

Install woodruff key to the wheel motor shaft. Slide

brake drum and hub onto the motor shaft.

6.

Remove retaining clip securing the cam shaft to the

brake lever. Separate lever from cam.

6.

Secure lock nut to the wheel motor shaft. Torque nut

from 250 to 400 ft–lb (34.6 to 55.3 kg–m).

NOTE: The brake assembly consists of return spring,

brake cam, brake shoes, backing plate, and anchor pin.

7.

Install rim to the drive studs. Secure rim with lug

nuts. Torque nuts from 40 to 50 ft–lb (5.5 to 6.9 kg–m).

7.

Remove brake assembly from the brake bracket by

removing four lock nuts and cap screws from the back-

ing plate and brake bracket. Do not disassemble.

8.

System).

Charge hydraulic system (see Charge Hydraulic

8.

Clean wheel motor and hydraulic connections. La-

bel all connections for reassembly.

NOTE: The right wheel motor has an extra hydraulic

tube and fitting attached to it.

9.

Disconnect hydraulic tubes and O–rings from the

hydraulic fittings. Allow tubes to drain into a suitable con-

tainer.

Sand Pro 2020/3020/5020

Page 4 – 61

Hydraulic System (Rev. A)

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro 3020, Toro 5020, Toro 98957SL.Toro 2020 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)