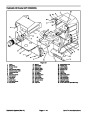

Removal (Fig. 86)

Before removing any parts from the hydraulic sys-

Installation (Fig. 86)

1.

NOTE: Apply antiseize lubricant or to the threads of cap

tem, park machine on a level surface, set brake, lower

attachment, and stop engine.

screws prior to installation.

1.

If the hydraulic tank (4 or 29) was separated from

the tank base (18), secure the base to the tank with three

cap screws (17), flat washers (21), and grommets (19).

Torque cap screws from 30 to 60 in–lb (35 to 69 kg–cm).

CAUTION

2.

the following:

If removed from the hydraulic tank (4 or 29), install

Operate all hydraulic controls to relieve system

pressure and avoid injury from pressurized hy-

draulic oil. Controls must be operated with the

ignition switch in OFF. Remove key from the igni-

tion switch.

A. O–ring (22) and 45o hydraulic fitting (5).

B. O–ring (25) and hydraulic fitting (16).

C. O–ring (37) and barb fitting (33).

D. Push on hose fitting (32).

2.

the machine.

Pivot seat up. Remove cover from the midsection of

3.

Unscrew knob from lift lever. Remove lift valve

shroud as explained in Lift Valve Removal and Installa-

tion (SP 2020/3020).

3.

frame. Secure base to the frame with three cap screws

Position tank (4 or 29) and tank base (18) to the

(10),

flat washers (9), and lock nuts.

4.

Clean hydraulic fittings and hydraulic hoses at-

tached to the hydraulic tank. Clean tank in the area of

these hoses.

4.

and fittings.

Remove caps or plugs from disconnected hoses

5.

Label all hydraulic connections for reassembly.

5.

Reconnect hose (28 or 30) to hydraulic fitting (5 or

32).

6.

Place a suitable container under hydraulic fitting (16

or 33) to collect hydraulic oil.

Disconnect hose (14 or 35) from hydraulic fitting (16

or 33). Allow fluid to drain completely from the tank into

the container.

6.

33).

Reconnect hose (14 or 35) to hydraulic fitting (16 or

Reinstall lift valve shroud as explained in Lift Valve

7.

7.

Removal and Installation (SP 2020/3020).

8.

or 32). Allow fluid to drain into a suitable container.

Disconnect hose (28 or 30) from hydraulic fitting (5

8.

9.

Screw knob onto lift lever.

Reinstall cover to the midsection of the machine.

9.

tings to prevent contamination.

Put caps or plugs on disconnected hoses and fit-

Pivot seat down.

10.

Hydraulic System Fluid and Change Hydraulic System

Oil and Filter).

Fill hydraulic tank with hydraulic fluid (see Check

10.

flat washers (9), securing the tank base (18) to the

frame. Pull tank and base from the frame.

Remove three lock nuts (15), cap screws (10), and

11.

Start machine. Run engine at lowest idle speed for

Inspection (Fig. 86)

3

to 5 minutes to circulate hydraulic fluid and remove any

air trapped in the system. Stop machine and recheck hy-

draulic tank level.

1.

vent.

Clean tank (4 or 29) and filler screen (20) with sol-

2.

3.

4.

Inspect tank for leaks, cracks, or other damage.

Replace hydraulic hoses if worn or leaking.

Make sure cap screws (17) fit tightly into the tank.

If loose, remove and reinstall cap screws with antiseize

lubricant on the threads. Torque cap screws from 30 to

60

in–lb (35 to 69 kg–cm).

5.

Make sure hydraulic fittings are tight and do not

leak.

Sand Pro 2020/3020/5020

Page 4 – 71

Hydraulic System (Rev. A)

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro 3020, Toro 5020, Toro 98957SL.Toro 2020 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)