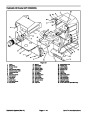

Removal (Fig. 87)

Before removing any parts from the hydraulic sys-

tem, park machine on a level surface, set brake, lower

attachment, and stop engine.

Cleaning and Inspection (Fig. 87)

1.

1. Back flush oil cooler with cleaning solvent (bottom

opening to top opening). After cooler is clean, make sure

all solvent is drained from the cooler.

CAUTION

CAUTION

Operate all hydraulic controls to relieve system

pressure and avoid injury from pressurized hy-

draulic oil. Controls must be operated with the

ignition switch in OFF. Remove key from the igni-

tion switch.

Use eye protection such as goggles when using

compressed air.

2.

Dry inside of oil cooler using compressed air in the

opposite direction of the oil flow (bottom opening to top

opening).

2.

Pivot seat up. Remove cover (8) from the midsec-

tion of the machine.

3.

Plug both ends of the oil cooler. Clean exterior of the

cooler. Make sure fins are clear of dirt and debris.

3.

Disconnect air hose attached to the air cleaner on

the engine.

4.

The oil cooler should be free of corrosion, cracked

tubes, and excessive pitting of tubes.

4.

Remove both lock nuts (12), cap screws (15), and

strip retainer (19) securing the lower part of the rubber

shield (20) to the frame. Position shield away from the

bottom of of the oil cooler (2).

Installation (Fig. 87)

1. Make sure hydraulic both openings to the oil cooler

are clean. Remove plugs from the cooler openings.

5.

Clean both 90o hydraulic fittings (5), hydraulic hose

and valve to cooler tube (6). Clean oil cooler (2) in

the area of these fittings.

(43),

2. Reinstall O–rings (29) and 90o hydraulic fittings (5)

to the oil cooler (2).

6.

Label all hydraulic connections for reassembly.

3. Position the oil cooler (2) to the front shield (26).

7.

(5)

oil.

Place a suitable container under 90o hydraulic fitting

at the bottom of the oil cooler (2) to collect hydraulic

4. Secure oil cooler to the front shield (26) with both

rubber clamps (3), flat washers (17), spacers (16), cap

screws (11), and T–nuts (4).

8.

Disconnect valve to cooler tube (6) from 90o hydrau-

lic fitting (5). Allow fluid to drain from into the container.

5. Remove caps or plugs on disconnected hoses and

fittings.

9.

Disconnect hydraulic hose (43) from 90o hydraulic

fitting (5). Allow fluid to drain completely from the cooler

into a suitable container.

6. Reconnect valve to cooler tube (6) to 90o hydraulic

fitting (5).

7.

Reconnect hydraulic hose (43) to 90o hydraulic fit-

ting (5).

10.

Put caps or plugs on disconnected hoses and fit-

tings to prevent contamination.

8.

Reinstall cover (8) to the midsection of the machine.

11.

Remove both cap screws (11), spacers (16), and flat

Pivot seat down.

washers (17) from rubber clamps (3) and T–nuts (4).

9.

Fill tank with hydraulic fluid (see Check Hydraulic

12.

13.

Pull the oil cooler (2) from the machine.

System Fluid and Change Hydraulic System Oil and Fil-

ter).

Remove 90o hydraulic fittings (5) and O–rings (29)

from the oil cooler (2).

10. Charge hydraulic system (see Charge Hydraulic

System).

Sand Pro 2020/3020/5020

Page 4 – 73

Hydraulic System (Rev. A)

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro 3020, Toro 5020, Toro 98957SL.Toro 2020 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)