Service and Repairs

Check Hydraulic Lines and Hoses

Check hydraulic lines and hoses daily for leaks, kinked

lines, loose mounting supports, wear, loose fittings,

weather deterioration and chemical deterioration. Make

all necessary repairs before operating.

WARNING

Keep body and hands away from pin hole leaks or

nozzles that eject hydraulic fluid under high pres-

sure. Use paper or cardboard, not hands, to

search for leaks. Hydraulic fluid escaping under

pressure can have sufficient force to penetrate

the skin and cause serious injury. If fluid is in-

jected into the skin, it must be surgically removed

within a few hours by a doctor familiar with this

type of injury. Gangrene may result from such an

injury.

Charge Hydraulic System

NOTE: When initially starting the hydraulic system with

new or rebuilt components such as motors, pumps, or

lift cylinders, it is important that the hydraulic system be

charged properly. Air must be purged from the system

and its components to reduce the chance of damage.

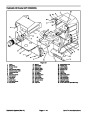

10. Loosen lock nut on spring adjusting pin until bearing

moves freely from cam. The pump shaft must be free to

rotate during start–up.

WARNING

IMPORTANT: Change hydraulic oil filter whenever

hydraulic components are repaired or replaced.

Before jacking up the machine, review and follow

Jacking Instructions in Chapter 1 – Safety.

1.

Park machine on a level surface, and turn the en-

gine off.

11.

blocks under frame. Chock remaining wheels to prevent

movement of the machine.

Raise one rear wheel off the floor, and place support

2.

components are secured tightly.

Make sure all hydraulic connections, lines, and

3.

contaminated, flush and refill hydraulic system and tank

(see Flush Hydraulic System).

If component failure was severe or the system is

12.

Make sure traction pedal and lift control lever are in

neutral. Start engine and run it at low idle of 1800 rpm.

The charge pump should pick up oil and fill the hydraulic

system. If there is no indication of fill in 30 seconds, stop

the engine and determine the cause.

4.

necessary (see Check Hydraulic System Fluid).

Make sure hydraulic tank is full. Add correct oil if

5.

Disconnect spark plug leads to prevent the engine

from starting.

2

6.

Check control linkage to the hydrostat for proper ad-

justment, binding, or broken parts.

7.

Make sure traction pedaland the lift control lever are

in the neutral position. Turn ignition key switch; engage

starter for fifteen (15)seconds to prime the traction and

charge pumps.

8.

Reconnect spark plug leads.

3

1

9.

move engine shield. On the SP 5020, remove cap

screws that secure side panel to right side of machine.

On the SP 2020/3020, pivot seat upward and re-

Figure 21

3. Cam

1.

2.

Spring adjusting pin

Bearing

Sand Pro 2020/3020/5020

Page 4 – 31

Hydraulic System (Rev. A)

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro 3020, Toro 5020, Toro 98957SL.Toro 2020 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)