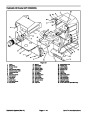

Removal (Fig. 26)

Before removing any parts from the hydraulic sys-

tem, park machine on a level surface, engage parking

brake, lower attachment, and stop engine.

Installation (Fig. 26)

1.

1. Make sure lift valve, hydraulic hoses, fittings, and

tubes are cleaned thoroughly.

2.

(2,

Reinstall O–rings (27 and 28) and hydraulic fittings

8, 9, and 10) to the lift valve. Observe match marks

CAUTION

when tightening.

3.

(7)

Position lift valve to the frame. Insert two cap screws

through the bottom two holes of frame bracket frame

Operate all hydraulic controls to relieve system

pressure and avoid injury from pressurized hy-

draulic oil. Controls must be operated with the

ignition switch in OFF. Remove key from the igni-

tion switch.

and lift valve. Screw lock nuts (1) to the bottom two cap

screws (7).

4. Position lift lever to the lift valve. Insert two cap

screws (7) through flat washer (24), pivot bracket (6),

and top two holes of lift valve and frame bracket. Screw

lock nut (1) to the top cap screw (7). Tighten all three lock

nuts and four cap screws.

2.

Remove cover from the midsection of the machine.

Unscrew knob (5) from lift lever (20).

3.

to the lift valve (see Control Panel Removal in Chapter

6

Remove control panel (right fender) to gain access

5.

cap screw (3) and lock nut (4). Tighten fasteners.

Secure welded pivot (21) to the lift valve stem with

– Wheels, Brakes, and Miscellaneous).

6.

hoses, tubes, and fittings

Remove caps and plugs from the disconnected

4.

tings, tubes, and hoses attached to it thoroughly.

Clean lift valve assembly (11) and all hydraulic fit-

7.

90

Reconnect hydraulic tube (31) and O–ring (26) to

o hydraulic fitting (2).

5.

6.

O–rings (29) from hydraulic fittings (8 and 9). Allow

hoses and fittings to drain into a suitable container.

Label all hydraulic connections for reassembly.

Disconnect both hydraulic hoses (32 and 33) and

8.

and O–rings (26) to hydraulic T–fitting (10).

Reconnect hydraulic hose (34), hydraulic tube (35),

9.

rings (29) to hydraulic fittings (8 and 9).

Reconnect both hydraulic hoses (32 and 33) and O–

7.

and O–rings (26) from hydraulic T–fitting (10). Allow

hose, tube, and fitting to drain into a suitable container.

Disconnect hydraulic hose (34), hydraulic tube (35),

10.

Reinstall control panel (see Control Panel Installa-

tion in Chapter 6 – Wheels, Brakes, and Miscellaneous).

8.

90

into a suitable container.

Disconnect hydraulic tube (31) and O–ring (26) from

o hydraulic fitting (2). Allow tube and fitting to drain

11.

Charge hydraulic system (see Charge Hydraulic

System).

9.

and fittings to prevent contamination.

Put caps or plugs on disconnected hoses, tubes,

12.

tubes, and fittings for leaks. Tighten as necessary.

Run machine and check lift valve, hydraulic hoses,

10.

the welded pivot (21) to the lift valve stem.

Remove cap screw (3) and lock nut (14) securing

13.

Adjust lift lever (20) (see Adjust Lift Lever).

11.

Remove four cap screws (7), lock washer (24) and

lock nuts (1) securing the pivot bracket (6) to the lift valve

and the lift valve to the frame. Separate lift valve from the

frame. Do not further disassemble parts assembled

to the lift lever.

IMPORTANT: Match mark positions of hydraulic fit-

tings (2,8,9 and 10) relative to their ports on the lift

valve.

12.

Remove remaining hydraulic fittings (2, 8, 9, and 10)

and O–rings (27 and 28) from the lift valve.

Sand Pro 2020/3020/5020

Page 4 – 37

Hydraulic System (Rev. A)

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro 3020, Toro 5020, Toro 98957SL.Toro 2020 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)