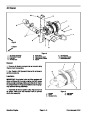

Manifold Service (Fig. 46)

Make sure the manifold isthoroughly cleaned before

4. Connect hydraulic hoses to hydraulic fittings on

manifold.

1.

removing either of the valves.

5. Install fuel tank to machine (see Fuel Tank Installa-

tion in Chapter 3 -- Gasoline Engine or Chapter 4 -- Die-

sel Engine).

IMPORTANT: Use care when handling the hydraulic

valve. Slight bending or distortion of the stem tube

can cause binding and malfunction.

6. Check hydraulic fluid level in reservoir (front axle)

and adjust as required (see Traction Unit Operator’s

Manual).

2.

Note correct location of o--rings, sealing rings and back-

up rings. Remove and discard seal kit from valves.

Using a deep socket, remove valves from manifold.

7. Follow Hydraulic System Start--up procedures.

3.

valves for damage to the sealing surfaces, damaged

threads and contamination.

Visually inspect the manifold port and removed

8. Check counterbalance valve adjustment (see Trac-

tion Unit Operator’s Manual).

A. Contamination may cause valve to stick or hang

up.Contaminationcanbecomelodgedinsmallvalve

orifices or seal areas causing valve malfunction.

2

B. If valve sealing surfaces appear pitted or dam-

aged, the hydraulic system may be overheating or

there may be water in the system.

25 ft--lb

3

(34

N--m)

CAUTION

20

(27

ft--lb

N--m)

Use eye protection such as goggles when using

compressed air for cartridge valve cleaning.

4

4.

Clean valves by submerging valve in clean mineral

1

spirits toflush outcontamination. Particles asfine astal-

cum powder can affecttheoperation ofthevalve. Beex-

tremely careful not to damage cartridge. Use

compressed air for cleaning.

Figure 46

5.

Lubricate new valve seal kit components with clean

hydraulic oil and install on valves. The o--rings, sealing

rings and backup rings must be arranged properly on

the valves for proper operation and sealing.

1.

2.

Manifold

3.

Check valve

Plug

Counterbalance valve

4.

6.

Thread valves carefully into correct manifold port.

The valves should go in easily without binding. Using a

deep socket, torque valves to values identified in Figure

46.

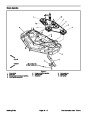

Installation (Fig. 45)

1.

Install all removed hydraulic fittings with new o--rings to

the manifold.

Coat new o--rings lightly with clean hydraulic oil.

2.

frame. Secure manifold to machine with two (2) cap

screws and flange nuts.

Position counterbalance valve manifold to machine

3.

Remove all caps or plugs from hydraulic hoses and

fittings.

Groundsmaster 3280--D/3320

Page 5 -- 59 Rev. A

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3280 D, Toro Groundsmaster 3320 |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)