2.

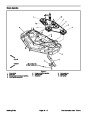

low verification of drive shaft alignment.

Attach the drive shaft directly to the engine hub to al-

2. Insert coupling spacers (item 8) into rubber cou-

plings. Position drive shaft assembly to engine and

pump hubs.

3.

Loosen square head screws (item 7) that secure

pump hub to transmission input shaft. Slide pump hub

toward engine, align holes in pump hub with drive shaft

flanges and place cap screws in holes.

3. Secure rubber coupling to engine hub with cap

screws (item 12), lock washers (item 13) and flat wash-

ers (item 3). Tighten cap screws so spacers are tight

against flat washers.

4.

Rotate drive shaft to check alignment of the drive

shaft in all positions. Drive shaft and hub must be

aligned within .125” (3 mm).

4. After attaching drive shaft to pump hub, make sure

that neither rubber coupling is deformed more than

.250”

(6.4 mm) in either direction. If necessary, remove

5.

If alignment adjustment is needed, loosen lock nut

and jam nut that secure transmission anchor (Fig. 27).

squareheadscrews(item7)frompumphub.Reposition

hub on shaft until coupling deflection is less than .250”

(6.4

of square head screws. Install screws into hub and

torque from 80 to 100 in--lb (9.0 to 11.3 N--m).

mm). Apply Loctite #242 (or equivalent) to threads

NOTE: If necessary, loosen the lift arm carrier bracket

before installing shims between frame and axle mount-

ing pad.

5.

Secure rubber coupling to pump hub with conelock

nuts (item 2), flat washers (item 3) and cap screws (item

Tighten cap screws so spacers are tight against flat

6.

Install shims between frame and axle mounting pads to

adjust location of transmission input shaft.

Loosen fasteners that secure front axle to frame.

10).

washers.

A. If the transmission input shaft is high at the drive

coupling, lower input shaft by installing shim(s) be-

tween the rearward axle mounting pads and the

frame (or by removing shim(s) that may exist at for-

ward mounting pads).

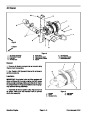

10

B. If the transmission input shaft is low at the drive

coupling, raise input shaft by installing shim(s) be-

tween the forward axle mounting pads and theframe

(or by removing shim(s) that exist at rearward axle

mounting pad).

11

1

7.

ers to secure front axle to frame.

Whendriveshaftalignmentiscorrect,tightenfasten-

9

IMPORTANT: Do not overtighten jam nut for trans-

mission anchor as drive shaft alignment will be af-

fected.

8

7

2

8.

Tighten upper jam nut (item 8) until it contacts top of

3

transmission anchor and then tighten lock nut (item 6)

below transmission anchor (Fig. 27).

4

6

5

Installation (Fig. 26)

Figure 27

IMPORTANT: Make sure that drive shaft alignment

is correct before installing drive shaft.

1.

2.

3.

4.

5.

6.

Transmission

7.

8.

9.

Transmission anchor

Jam nut

Shim

Flat washer

Cap screw

Carrier bracket

Lock nut

Front axle

10. Cap screw

1.

Insert coupling spacers (item 5) into rubber coupling

11. Lock nut

holes. Secure rubber couplings to drive shaft with con-

elock nuts (item 2) and cap screws (item 6). Tighten so

spacers are tight against drive shaft.

Groundsmaster 3280--D/3320

Page 5 -- 33

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3280 D, Toro Groundsmaster 3320 |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)