Charge Pump Flow Test (Using Tester With Pressure Gauges and Flow Meter)

The charge pump flow test should be performed if a hy-

draulicproblemisidentifiedthataffectsboththesteering

and lift circuits.

IMPORTANT: The charge pump is a positive dis-

placement pump. If the flow control valve on the

tester is fully closed, transmission damage can oc-

cur.

NOTE: The charge pump provides make--up oil for in-

ternal hydrostat components before flow is available for

the steering and lift circuits. Flow measured in this test

will be less than total charge pump output.

9. Watch tester pressure gauges carefully while slowly

closingtheflowcontrolvalveuntilpressuregaugereads

500 PSI (34.5 bar).

1.

perature by operating the machine for approximately 10

minutes.

Make sure hydraulic oil is at normal operating tem-

10.Flow gauge reading should be at least 1 GPM (3.8

LPM).

11.

Open flow control valve on tester and turn offengine.

2.

Parkmachineonalevelsurfacewiththecuttingdeck

Record results of hydraulic flow test.

(or implement) lowered and P.T.O. switch off. Make sure

engine is off. Set the parking brake and block the front

wheels to prevent machine movement.

12.If

pressureof500PSI(34.5bar)orflowof1GPM(3.8

LPM) could not be achieved, check the following:

A. Perform the charge pressure test (see Charge

Pressure Test in this section). Also, a dynamic

charge pressure test can be performed to identify ifa

worn or damaged hydrostatic transmission exists.

3.

Read Precautions For Hydraulic Testing.

CAUTION

B. Perform the implement relief pressure test (see

Implement Relief Pressure Test in this section).

Before opening hydraulic system, operate all

hydraulic controls to relieve system pressure

and avoid injury from pressurized hydraulic oil.

C. Inspect the condition of the charge pump gerotor

and internal housing (See Charge Pump Service in

the Sauer--Danfoss (Sundstrand) 15 Series Service

Manual at the end of this chapter).

4.

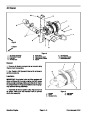

Placeadrainpanunderthetransmission.Thorough-

ly clean the area around the transmission charge pump

outlet(pressure)fitting(Fig.23).Disconnectthehydrau-

lic hose from the outlet fitting.

D. The general condition of the transmission’s pis-

ton pump and piston motor might be suspected of

wear and inefficiency.

IMPORTANT: Make sure that the oil flow indicator

arrow on the flow meter is showing that the oil will

flow from the pump, through the tester and to the

hydraulic hose.

13.Disconnect testerfromthetransmission andhydrau-

lic hose. Reconnect hydraulic hose to the transmission

fitting. Check hydraulic oil level in reservoir (front axle).

5.

Connect inlet hose of tester with pressure gauges

4

3

and flow meter to the transmission charge pump outlet

(pressure) fitting. Connect the tester outlet hose to the

hydraulic hose disconnected from the transmission fit-

ting in step 5.

6.

Make sure that the flow control valve on the tester is

2

fully open. Also, make sure that traction pedal and lift

valve are in neutral and that the parking brake is en-

gaged.

FRONT

1

7.

draulic leakage from test connections and correct be-

fore proceeding with test.

Start engine and run at idle speed. Check for any hy-

Figure 23

1.

2.

Hydrostatic transmission

Hydraulic hose

3.

4.

O--ring

Outlet fitting

8.

tachometer to verify that engine speed is correct.

Run engine at full speed (3200 + 50 RPM). Use a

Hydraulic System

Page 5 -- 26

Groundsmaster 3280--D/3320

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3280 D, Toro Groundsmaster 3320 |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)