Lift Circuit

The hydrostatic transmission charge pump supplies

charge oil for the closed loop traction circuit in addition

to supplying flow for the steering circuit and the cutting

deck (or implement) lift circuit. The charge pump takes

its suction through a filter from the reservoir (front axle).

Pump output flows to the steering control valve before

reaching the lift valve so the steering circuit has priority.

Liftcircuitpressureislimitedfrom700to1000PSIbythe

implement relief valve located in the hydrostat.

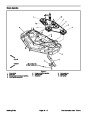

Lower Cutting Deck (Or Implement) (Fig. 10)

When the cutting deck (or implement) is to be lowered,

the control valve spool is moved forward causing the pi-

lot valve to shift. This shifted valve allows a return path

from the lift cylinders to the reservoir (front axle) (Fig.

10).

The weight of the cutting deck (or implement)

causes the cylinders to retract thus lowering the cutting

deck(orimplement).Asthecylindersretract,thepistons

draw hydraulic fluid from the reservoir (front axle) into

the lower portion of the lift cylinders.

During conditions of not steering or raising/lowering the

cutting deck (or implement), flow from the charge pump

goes to the lift control valve and is by--passed through

the oil cooler and then to the reservoir (front axle).

When the control valve lever is released, the lift control

spool returns to the center position and causes the pilot

valve to shift. Oil flow by--passes to the reservoir (front

axle) and lift cylinder movement is stopped.

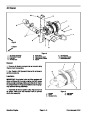

Raise Cutting Deck (Or Implement) (Fig. 9)

Whenthecutting deck(orimplement)istoberaised,the

control valve spool is positioned back and flow is di-

rected out the B port of the control valve to the cylinder

(upper) end of the lift cylinders. Hydraulic pressure

against the cylinder pistons extends the lift cylinders. At

the same time, the pistons push the hydraulic fluid in the

lower portion of the lift cylinders out and to the reservoir

(front axle). The extending lift cylinders cause the cut-

ting deck (or implement) to raise.

Counterbalance

An adjustable counterbalance valve allows cutting unit

weight transfer to the machine to improve traction. On

early production machines, the counterbalance valve is

incorporated in the lift control valve. Later production

machines have a separate counterbalance manifold.

Changes in traction conditions (e.g. moving up an in-

cline) will cause a valve shift to slightly lift or lower the

cutting deck to alter weight transfer. Counterbalance

pressure settings are dependant on the cutting deck

used on a machine. Refer to Traction Unit Operator’s

Manual for counterbalance pressure recommenda-

tions.

When the control valve lever is released, spring action

returns the lift control spool to the center position and

by--passesflowbacktothereservoir (frontaxle).Liftcyl-

inder movement is stopped.

LIFT CIRCUIT (LOWER)

Figure 10

Page 5 -- 11 Rev. A

Groundsmaster 3280--D/3320

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3280 D, Toro Groundsmaster 3320 |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)