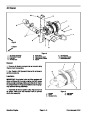

Rear Axle Spindle Bushings (Fig. 5)

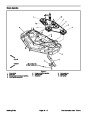

7. Install two thrust washers (items 10 and 5) onto the

spindle shaft and slide the shaft up through the axle

tube. Hold the wheel and spindle shaft assembly in

place and install the flat washer(s) (items 7 and 6), thrust

washer (item 5) and retaining ring (item 4) onto the end

of the spindle shaft.

The rear wheel spindles must fit snugly in the rear axle.

Excessive movement of the spindle in the axle indicates

that the spindle bushings (item 8) are probably worn and

must be replaced.

1.

moval in this section).

Remove rear axle from machine (see Rear Axle Re-

8.

mm) after assembly. If necessary, adjust end play by

adding or removing flat washers (items 6 and 7).

End play of spindle should be .030” to .090” (.8 to 2.3

2.

Remove two (2) jam nuts and flat washer that secure

the tie rod end to the spindle arm. Disconnect the tie rod

end from the spindle arm.

9.

Install the spindle cap and cap screw.

the tie rod end to the spindle bracket with

10.Connect

3.

Remove the flange screw, spindle cap, retaining ring

flat washer and two (2) jam nuts. Tighten the first jam nut

and then tighten the second jam nut against the first to

secure tie rod end to spindle.

and washers that secure the wheel spindle into the axle

tube. Slide the spindle, washers and wheel assembly

out of the axle tube to expose the spindle bushings.

11.

tion in this section).

Install rear axle to machine (see Rear Axle Installa-

4.

Use a punch and hammer to drive both bushings out

of the axle tube. Take care not to damage the inside of

the axle tube. Clean the inside of the axle tube to remove

any dirt or foreign material.

12.Lubricate the steering spindles through the grease

fittings on the rear axle (see Traction Unit Operator’s

Manual).

5.

Apply grease to the inside and outside of the new

bushings. Use an arbor press to install the bushings into

the top and bottom of the axle tube. The bushings must

be flush with the axle tube.

13.Check rear wheel toe−in (see Traction Unit Opera-

tor’s Manual).

14.After

all adjustments have been made, make sure

6.

spindle for wear and replace if worn or damaged.

Thoroughly clean the spindle shaft. Inspect the

that no contact is made between any steering compo-

nents as the wheels are moved from lock to lock. Re-

adjust if necessary.

Chassis

Page 7 − 14

Groundsmaster 3280−D/3320

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3280 D, Toro Groundsmaster 3320 |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)