4.

P.T.O. Drive Shaft Removal in Service and Repairs sec-

tion of Chapter 9 − P.T.O. System).

Disconnect P.T.O. drive shaft from gearbox (see

9. Connect P.T.O. drive shaft to gearbox (see P.T.O.

Drive Shaft Installation in Service and Repairs section

of Chapter 9 − P.T.O. System).

5.

ers (item 16) that secure gearbox assembly to gearbox

brackets.

Remove four (4) cap screws (item 17) and lock wash-

10.Install drive belt and belt covers to cutting deck (see

Cutting Unit Operator’s Manual).

11.

Torque plug in gearbox to 175 in−lb (19.8 N−m). Fill

6.

bracket (item 12) to deck mounting plate. Remove

bracket from deck.

Remove fasteners that secure left side gearbox

gearbox with lubricant (see Cutting Unit Operator’s

Manual). Install dipstick in gearbox and torque to 175 in−

lb (19.8 N−m).

7.

Remove gearbox assembly with drive pulley at-

tached from deck. Drain lubricant from gearbox.

2

8.

Remove two (2) set screws that secure taper lock

bushing to drive pulley on gearbox shaft.

1

9.

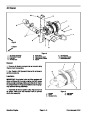

Thread one of the removed set screws into threaded

1

hole of bushing (Fig. 10). Tighten set screw to loosen

bushing from pulley hub.

10.Slide

bushing and pulley from gearbox shaft. Locate

and retrieve woodruff key.

Figure 10

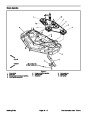

11.

caps in gearbox (Fig. 11).

If necessary, remove and replace oil seals and oil

1.

2.

Set screw installation position

Set screw removal position

NOTE: If internal gearbox wear or damage occurs,

gearbox replacement is necessary. Internal gearbox

components are not available.

175

in−lb

175

(19.8

in−lb

N−m)

1

(19.8 N−m)

Installation (Fig. 9)

1.

If oil seals or seal caps were removed, use a press

2

6

to install seals or caps so they are flush with the gearbox

housing. With seals installed, rolling torque for gearbox

input shaft should be 5 to 10 in−lb (.56 to 1.13 N−m).

2.

Clean gearbox output shaft, pulley ID and taper lock

bushing thoroughly.

3

3.

Position woodruff key, pulley and then taper lock

bushing to gearbox output shaft. Slide bushing to shoul-

der on shaft. Align threaded holes of pulley with non−

threaded holes of bushing.

4

4.

Lightly oil threads of set screws and install screws

into threads of pulley (Fig. 10). Alternately and evenly

tighten set screws to a torque of 175 in−lb (19.8 N−m).

5

5.

Fill allen recess in set screws and bushing threads

with grease to prevent dirt from packing into crevices.

Figure 11

6.

Position gearbox assembly with drive pulley at-

tached to deck.

1.

2.

3.

Oil cap

Dipstick

Oil cap

4.

5.

6.

Gearbox

Oil seal

Plug

7.

Position and secure left side gearbox bracket (item

to deck mounting plate.

12)

8.

Secure gearbox assembly to gearbox brackets with

four (4) cap screws (item 17) and lock washers (item 16).

Groundsmaster 3280−D/3320 Page 10 − 13

Cutting Units

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3280 D, Toro Groundsmaster 3320 |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)