9.

Remove the bevel gear case/axle case assembly

NOTE: Axle bearing shims are available in 0.008 in.

(0.20 mm), 0.012 in. (0.30 mm) and 0.020 in. (0.50 mm)

thickness.

from the axle support. Coat a new O-ring with grease

and temporarily install the axle cover assembly. Position

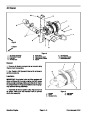

a dial indicator at the tooths center. Prevent the axle

from turning and measure the lower bevel gear to axle

gear backlash (Fig. 72).

11.

27

Tighten axle cover screws from 17 to 20 ft-lb (23 to

N−m).

12.Coat

a new O-ring with grease and install the bevel

LOWER BEVEL GEAR BACKLASH:

gear case/axle case assembly on the axle support.

Tighten mounting screws and nuts from 35 to 41 ft-lb (47

to 56 N−m) (Fig. 73).

0.004

to 0.016 in. (0.10 to 0.40 mm)

10.Adjust

backlash by increasing or reducing axle bear-

ing shim thickness (see Axle Shafts in this section of this

manual).

Differential Shafts (4 Wheel Drive Axle)

The following procedures assume the 4WD rear axle as-

sembly has been removed from the machine.

35

(47

to 41 ft−lb

to 56 N−m)

Removal

1

6

5

IMPORTANT: Do not interchange right and left dif-

ferential shafts assemblies. Mark right and left

shafts before disassembly.

4

2

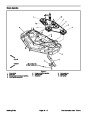

1.

ers. Remove the bevel gear case/axle case assembly

and O-ring from the axle support (Fig. 73).

Remove the mounting screws, nuts and lock wash-

3

35

(47

to 41 ft−lb

to 56 N−m)

2.

Mark and pull the differential shaft assembly from the

axle support.

Figure 73

1.

2.

3.

4.

Cap screw

Lock nut

Lock washer

Axle support

5.

case assembly

6.

Bevel gear case/axle

3.

4.

Remove the retaining ring and bevel gear (Fig 74).

Drive the differential shaft out of the bearings. Re-

O-ring

move the bearings and bearing shims.

5.

Inspect all gears, shafts, bearings and cases for

damage and wear. Replace components as necessary.

Installation

6

1.

Press bearings onto differential shaft. Place correct

3

combination of bearing shims in axle support and drive

differential shaft and bearing assembly into axle sup-

port.

5

4

2

1

2.

3.

Install bevel gear and retaining ring.

Coat new O-ring with grease. Align differential shaft

splines with differential gear assembly and slide differ-

ential shaft assembly onto axle support.

Figure 74

4.

5.

6.

4.

Bevel Gear Case/Axle Case Assembly in this section of

this manual).

Install bevel gear case/axle case assembly (see

1.

2.

3.

Retaining ring

Bevel gear

Differential shaft

Bearing

Bearing shims

O-ring

Drive Axles

Page 8 − 40

Groundsmaster 3280−D/3320

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3280 D, Toro Groundsmaster 3320 |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)