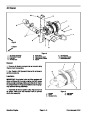

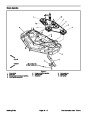

Removal (Fig. 36)

Park the machine on a level surface, engage the

parkingbrake,lowerthecuttingdeck(orimplement)and

stop the engine. Remove the key from the ignition

switch.

2. Position steering cylinder to machine. Make sure to

place spacer ring (item 13) and washer (item 9) in loca-

tions noted during removal (Fig. 37).

1.

3. Secure steering cylinder to machine with capscrews

(items 12 and 6) and lock nuts (items 7 and 11). Torque

lock nuts from 130 to 150 ft--lb (176 to 203 N--m).

2.

Read the General Precautions for Removing and

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

4. Remove caps and plugs from hydraulic hoses and

fittings.

5. Correctly connect hydraulic hoses to steering cylin-

der.

CAUTION

6.

and adjust as required (see Traction Unit Operator’s

Manual).

Check hydraulic fluid level in reservoir (front axle)

Operate all hydraulic controls to relieve system

pressure and avoid injury from pressurized hy-

draulic oil.

7.

Lubricate cylinder grease fittings (see Traction Unit

Operator’s Manual).

3.

Label all hydraulic connections for assembly pur-

poses.Cleanhydraulichoseendspriortodisconnecting

the hoses.

8. Follow Hydraulic System Start--up procedures.

9.

Check that steering cylinder does not contact the

4.

5.

Disconnect hydraulic hoses from steering cylinder.

Putcaps or plugs on disconnected hoses andfittings

axle or frame as cylinder moves from fully retracted to

fully extended.

to prevent contamination.

1

9

6.

Remove cap screws (items 12 and 6) and lock nuts

(items 7 and 11) that secure steering cylinder to ma-

chine.

7.

trievespacerring(item13)andwasher(item9)andnote

location for installation purposes (Fig. 37).

Pull steering cylinder from machine. Locate and re-

2

8

6

3

5

8.

Removehydraulic fittingsfromsteeringcylinder ifre-

4

7

quired. Note orientation of 45o fitting before removing

from steering cylinder.

Figure 37

Installation (Fig. 36)

1.

2.

3.

4.

5.

Cap screw

Washer

Steering pivot mount

Lock nut

Steering cylinder

6.

7.

8.

9.

Spacer ring

Cap screw

Axle cylinder mount

Lock nut

1.

Coatnewo--ringslightly withcleanhydraulicoil.Ifre-

moved, install hydraulic fittings with new o--rings to the

steering cylinder. Make sure that 45ofitting is positioned

correctly.

Groundsmaster 3280--D/3320

Page 5 -- 47

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3280 D, Toro Groundsmaster 3320 |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)