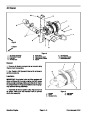

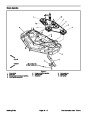

Removal (Fig. 2)

Park the machine on a level surface, engage the

parking brake, lower the cutting deck (or implement) and

stop the engine. Remove the key from the ignition

switch.

Installation (Fig. 2)

1.

1. If removed, secure pivot plate (item 27) to steering

column with two (2) cap screws (item 15) and flange nuts

(item 22).

2.

Slide steering column onto steering control valve.

2.

Carefully remove steering wheel cover from steering

Position spacers (items 16 and 18) to steering column.

wheel.

3.

Attach steering column to frame with flange screws

3.

Remove hex nut that secures steering wheel to

(items 4 and 17) and flange nuts (item 14).

steering column.

4.

Secure steering column to steering control valve with

4.

umn.

Pull steering wheel and foam collar from steering col-

four (4) socket head screws (item 20) and spring wash-

ers (item 19).

5.

Remove knob from end of parking brake rod.

5. Apply antiseize lubricant onto threads and rod of tilt

steering lever (item 11). Position friction washer (item

6.

Remove six (6) phillips head screws that secure tow-

23)

between steering tower and pivot plate (item 24).

er panel to machine. Remove tower panel.

Remove flange head screw (item 17) and flange nut

(item 14) that secure tilt bracket (item 27) to steering

tower. Slide tilt bracket off jam nut.

Install tilt lever through steering tower boss, friction

washer and pivot plate. Place friction washer (item 25)

and flat washer (item 26) onto lever and thread jam nut

(item 21) onto lever.

7.

6.

so lever handle is secured in the up position (90o + 10o

from horizontal).

Torque jam nut from 20 to 23 ft−lb (27.1 to 31.2 N−m)

8.

Loosen and remove jam nut (item 21). Remove tilt

steering lever from steering tower. Locate and retrieve

friction washers (items 23 and 25) and flat washer (item

26).

7.

Position tilt bracket (item 27) onto jam nut and secure

to steering tower with flange head screw (item 17) and

flange nut (item 14).

9.

(item 20) and spring washers (item 19) that secure

steering control valve to steering column.

Loosen and remove four (4) socket head screws

8.

Position tower panel to machine and secure with six

phillips head screws.

(6)

10.Loosen

and remove flange screws (items 4 and 17)

and flange nuts (item 14) that attach steering column to

frame.

9.

Install knob on end of parking brake rod.

10.Slide

foam collar onto steering column.

11.

Slide steering column from steering control valve

and remove from machine. Locate and retrieve two (2)

spacers (items 16 and 18).

11.Slide steering wheel onto steering column and se-

cure with hex nut. Torque hex nut from 20 to 26 ft−lb

(27.1

to 35.3 N−m).

12.If

necessary, remove two (2) cap screws (item 15)

and flange nuts (item 22) that secure pivot plate (item

to steering column.

12.Install steering wheel cover onto steering wheel.

27)

Groundsmaster 3280−D/3320

Page 7 − 7 Rev. A

Chassis

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3280 D, Toro Groundsmaster 3320 |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)