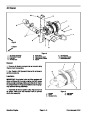

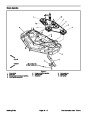

Removal (Fig. 4)

Park machine on a level surface, lower cutting deck

(or implement), stop engine, engage parking brake and

remove key from the ignition switch.

Installation (Fig. 4)

1.

1. Thoroughly clean the rear axle pivot pin. Inspect the

pin for wear or damage and replace if necessary.

2.

Position the axle to the rear frame. Install small ID

NOTE: To ease reassembly, tag hydraulic hoses to

show their correct position on the steering cylinder.

thrust washer (item 17) in front of axle tube and large ID

thrust washer (item 24) directly behind axle tube. Place

shim washer(s) (item 25) as required between large ID

thrust washer and rear frame to allow .030” to .090” (.8

to 2.3 mm) axle tube end play. Slide pivot pin through

rear frame, washers and axle.

2.

Disconnect the hydraulic hoses from the steering

cylinder. Put caps or plugs on all fittings and hoses to

prevent contamination.

3.

of the axle pivot pin (item 29) to the rear frame.

Remove the lock nut (item 23) that secures the end

3.

28),

Secure pivot pin to rear frame with cap screw (item

flat washer (item 27) and lock nut (item 26).

4.

Jack up the machine (just ahead of the rear wheels)

4.

Tighten lock nut (item 23) until shoulder of pivot pin

until pressure is taken off the axle pivot pin. Support the

machine with jack stands to prevent it from falling.

bottoms against the rear frame. Make sure that axle can

still pivot freely after lock nut is tightened.

5.

flat washer (item 27) that secure pivot pin to rear frame.

Remove lock nut (item 26), cap screw (item 28) and

5.

ground.

Remove the jackstands and lower the machine to the

NOTE: Several washers (items 17, 24 and 25) are

installed between the axle pivot tube and rear frame to

adjust clearance between axle pivot tube and rear

frame. Before removing axle pivot pin, note location of

washers.

6.

Install the hydraulic hoses to the steering cylinder.

7. Check oil level in hydraulic reservoir (front axle) (see

Traction Unit Operator’s Manual).

8.

Lubricate the rear axle pivot bushings through the

6.

Pull the axle pivot pin out. This will release the rear

grease fitting on the axle pivot tube (see Traction Unit

Operator’s Manual).

axle and washer(s) from the frame. Carefully pull the en-

tire axle and wheel assembly out from under the ma-

chine.

9.

Operate machine and check steering cylinder hy-

draulic connections for leaks.

7.

Locate and retrieve thrust washers (items 17 and 24)

and shim washer(s) (item 25).

Groundsmaster 3280−D/3320

Page 7 − 11

Chassis

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3280 D, Toro Groundsmaster 3320 |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)