15.Disconnect

wire harness connectors from the follow-

ing engine components:

5

NOTE: Label all electrical leads for reassembly pur-

poses.

4

3

3

A. Alternator connector and stud.

B. High temperature shut down switch and temper-

ature sender located on the water pump housing.

4

6

C. Fuel solenoid on carburetor.

D. Oil pressure switch located near the engine oil

dipstick.

3

2

1

E. Ignition coils located on the right side of the en-

gine.

4

3

7

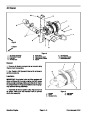

Figure 15

F. Connector, fusible link connector and positive

battery cable from the starter motor.

1.

2.

3.

4.

Gasoline engine

Engine bracket

Flat washer

5.

6.

7.

Pivot plate

Engine bracket

Engine bracket

Cap screw

G. Wire harness ground wire from the muffler brack-

et.

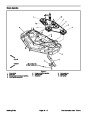

Installation (Fig. 11)

Locate machine on a level surface with cutting deck

H. P.T.O. clutch wire connector.

I. Crank position wire connector.

1.

(or implement) lowered and key removed from the igni-

tion switch. Chock wheels to keep the machine from

moving.

16.Remove

engine from machine:

2.

during maintenance or rebuilding are reinstalled to the

engine.

Make sure that all parts removed from the engine

A. Attach short section of chain between lift tabs lo-

cated on each end of the cylinder head.

B. Connect a hoist or chain fall at the center of the

short section of chain. Apply enough tension on the

short chain so that the engine will be supported.

3.

reinstall them to engine (Fig. 15).

If engine brackets were removed from the engine,

4.

If engine mount brackets (items 20 and 28) were re-

C. Remove fasteners that secure the engine (with

brackets) to the engine shock mounts and engine

mount brackets.

moved from frame, secure them to frame with cap

screws and lock washers. Torque screws from 50 to 60

ft−lb (68 to 81 N−m).

IMPORTANT: The left, rear shock mount (item 15) is

different than the other three mounts (item 19). If

shock mounts were removed from engine mount

brackets on frame, make sure that shock mount

with red patch is correctly installed at left, rear posi-

tion.

CAUTION

One person should operate lift or hoist while the

other person guides the engine out of the ma-

chine.

5.

6.

Position fan shroud around the engine fan.

Reinstall engine to machine.

IMPORTANT: Make sure not to damage the engine,

fuel hoses, hydraulic lines, electrical harness or

other parts while removing the engine.

A. Attach short section of chain between lift tabs lo-

cated on each end of the cylinder head

D. Raise engine and remove from machine.

17.If

(Fig. 15).

necessary, remove engine brackets from engine

B. Connect a hoist or chain fall at the center of the

short section of chain. Apply enough tension on the

short chain so that the engine can be supported.

Gasoline Engine

Page 3 − 14

Groundsmaster 3320

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3280 D, Toro Groundsmaster 3320 |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)