P.T.O. Electric Clutch

Removal (Figs. 39 and 40)

1.

Park machine on a level surface, lower cutting deck

9

(or implement), stop engine, engage parking brake and

remove key from the ignition switch.

Antiseize

Lubricant

10

2.

Unplug clutch connector from machine wire harness.

3

3.

Remove P.T.O. belt from clutch and P.T.O. shaft

pulley (see Traction Unit Operator’s Manual).

4.

Remove clutch stop components using Figure 39

(Groundsmaster 3280−D) or Figure 40 (Groundsmaster

as a guide.

11

4

5

6

2

7

8

1

3320)

Loctite #242

NOTE: Hold coupler on front of engine to prevent

crankshaft from turning when removing cap screw that

secures clutch to stub shaft.

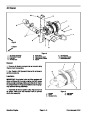

Figure 39

1.

Cap screw

Spacer

Electric clutch

Square key

Stub shaft

7.

8.

9.

10. PTO pulley

11. PTO belt

Clutch stop

Flange nut

Diesel engine

2.

3.

4.

5.

6.

5.

Remove cap screw and spacer that secure clutch to

stub shaft.

Flange head screw

NOTE: It may be necessary to lower the rear frame and

axle assembly to allow clutch removal (see Rear Frame

and Axle Assembly Removal in the Service and Repairs

section of Chapter 7 − Chassis).

Loctite #242

9

8

6

5

6.

Slide clutch from shaft. Locate and retrieve square

2

key.

7

Installation (Figs. 39 and 40)

1

1.

Apply antiseize lubricant to stub shaft.

3

2.

Position square key in stub shaft. Slide clutch onto

shaft making sure to engage clutch stop.

Antiseize

Lubricant

4

NOTE: Hold coupler on front of engine to prevent

crankshaft from turning when installing cap screw that

secures clutch to stub shaft.

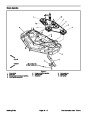

Figure 40

1.

2.

3.

4.

5.

Cap screw

Spacer

Electric clutch

Stub shaft

Gasoline engine

6.

7.

8.

9.

Mounting bracket

Square key

Clutch stop

3.

Apply Loctite #242 (or equivalent) to threads of cap

screw. Secure clutch to shaft with spacer and cap screw.

Flange head screw

4.

Install clutch stop components using Figure 39

(Groundsmaster 3280−D) or Figure 40 (Groundsmaster

as a guide. Make sure that clutch stop is tight

against clutch flange.

3320)

5.

Check alignment between clutch pulley and P.T.O.

shaft pulley (see Align P.T.O. Pulley to Electric Clutch

Pulley in Service and Repairs section of Chapter 9 −

P.T.O. System).

6.

Install P.T.O. belt to clutch and P.T.O. shaft pulley and

adjust P.T.O. belt tension (see Traction Unit Operator’s

Manual).

7.

Connect clutch to machine wire harness.

Electrical System

Page 6 − 32

Groundsmaster 3280−D/3320

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3280 D, Toro Groundsmaster 3320 |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)