5.

P.T.O. shaft. Using a puller, remove pulley from P.T.O.

shaft. Locate and retrieve woodruff key.

Remove cap screw and washer that secure pulley to

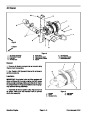

4. Secure P.T.O. bearing bracket to frame with four (4)

cap screws and lock washers (Fig. 6).

5.

Secure rear bearing flange to P.T.O. pivot shaft with

6.

Loosen set screws that secure front and rear flange

two (2) carriage screws and lock nuts.

bearing locking collars to P.T.O. shaft. Using the blind

hole in each bearing collar as a striking point, unlock col-

lars from P.T.O. shaft with a punch by rotating the collars

clockwise as viewed while facing forward.

6.

Thoroughly clean tapers of P.T.O. shaft and pulley.

Apply antiseize lubricant to P.T.O. shaft taper. Position

woodruff key into shaft slot. Install pulley onto P.T.O.

shaft.

7.

8.

Support P.T.O. shaft to prevent it from falling.

7.

screw that secures pulley to P.T.O. shaft. Secure pulley

to P.T.O. shaft with cap screw and washer.

Apply Loctite #242 (or equivalent) to threads of cap

Remove two (2) carriage screws and lock nuts that

secure rear bearing flange to the P.T.O. pivot shaft.

9.

secure P.T.O. bearing bracket to frame (Fig. 6).

Remove four (4) cap screws and lock washers that

8. Install P.T.O. drive belt to machine (see Traction Unit

Operator’s Manual). Do not fully tension belt.

IMPORTANT: Make sure not to damage hydraulic

lines or other parts while removing the P.T.O. shaft

from machine.

9. Align P.T.O. pulley to electric clutch pulley (see Align

P.T.O. Pulley to Electric Clutch Pulley in this section).

10.After

pulleys are aligned properly, make sure that

10.Carefully

chine.

lower P.T.O. shaft and remove from ma-

flange bearing locking collars are locked to P.T.O. shaft

and secured with set screws. Torque set screws from 85

to 100 in−lb (9.6 to 11.3 N−m). Also, make sure that

P.T.O. drive belt is properly tensioned (see Traction Unit

Operator’s Manual).

11.

Slide flange bearings, bearing bracket and support

plate from P.T.O. shaft.

12.If

ing bracket and support plate using Figure 5 as a guide.

required, disassemble front flange bearing, bear-

11.

Rear Frame and Axle Assembly Installation in the Ser-

vice and Repairs section of Chapter 7 − Chassis).

Install rear frame and axle assembly to machine (see

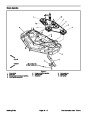

Installation (Fig. 5)

12.Install

Shaft Installation in this section).

P.T.O. drive shaft to machine (see P.T.O. Drive

1.

bearing bracket and support plate:

If separated, assemble front front flange bearing,

A. Secure flange bearing to support plate with two

(2)

carriage screws and hex nuts.

B. Lubricate rubber mounts with soapy water and

install mounts into support plate. Make sure that

mounts slide completely into support plate.

1

2

C. Secure support plate to bearing bracket with cap

screws, washers and lock nuts. Make sure that

washers are placed on both sides of rubber mounts.

D. Make sure that bearing support plate is fully

seated against shoulders of rubber mounts and also

is parallel within .120” (3.0 mm) to bearing bracket.

2.

Install flange bearings onto P.T.O. shaft with locking col-

lars orientated toward front of shaft.

Apply antiseize lubricant to flange bearing bores.

Figure 6

2.

1.

P.T.O. shaft

P.T.O. bearing bracket

IMPORTANT: Make sure not to damage hydraulic

lines or other parts while installing the P.T.O. shaft

to machine.

3.

Carefully raise P.T.O. shaft to machine.

Groundsmaster 3280−D/3320

Page 9 − 9

P.T.O. System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3280 D, Toro Groundsmaster 3320 |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)