9.

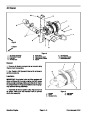

Disconnect fuel hoses from standpipe (item 22) and

DANGER

elbow fitting (item 20) on the top of the fuel tank.

10.Remove

fuel tank using Figure 6 as a guide.

Because gasoline is highly flammable, use cau-

tion when storing or handling it. Do not smoke

while filling the fuel tank. Do not fill fuel tank

while engine is running, hot, or when machine is

in an enclosed area. Always fill fuel tank outside

and wipe up any spilled fuel before starting the

engine. Store fuel in a clean, safety−approved

container and keep cap in place. Use gasoline

for the engine only; not for any other purpose.

Fuel Tank Installation (Fig. 6)

1.

2.

Install fuel tank to frame using Figure 6 as a guide.

Connect fuel hoses to standpipe (item 22) and elbow

fitting (item 20) on the top of the fuel tank. Secure hoses

with clamps.

3.

Secure lower control panel to machine with flange

head screws and flange nut (Fig. 7).

Check Fuel Lines and Connections

4.

Secure tank to left fender with flat washer (item 32)

Check fuel lines and connections periodically as recom-

mended in the Traction Unit Operator’s Manual. Check

lines for deterioration, damage, leaking or loose con-

nections. Replace hoses, clamps and connections as

necessary.

and lock nut (item 31).

5.

Position control panel to fuel tank, connect wire har-

ness to panel components and secure panel to machine

with thumb screws.

6.

7.

Standard Seat or Suspension Seat Installation in Ser-

vice and Repairs section of Chapter 7 − Chassis).

Install seat plate to machine.

Drain and Clean Fuel Tank

Install seat suspension and seat to machine (see

Drain and clean the fuel tank periodically as recom-

mended in the Traction Unit Operator’s Manual. Also,

drain and clean the fuel tank if the fuel system becomes

contaminated or if the machine is to be stored for an ex-

tended period.

8.

hood.

Connect seat switch to machine wire harness. Close

To clean fuel tank, flush tank out with clean solvent.

Make sure tank is free of contaminates and debris.

9.

Fill fuel tank (see Traction Unit Operator’s Manual).

Fuel Tank Removal (Fig. 6)

3

1.

Park machine on a level surface, lower cutting deck

2

(or implement), stop engine, engage parking brake and

remove key from the ignition switch. Open hood.

2

4

2.

Unplug seat switch from machine wire harness.

1

3.

(see Standard Seat or Suspension Seat Removal in

Service and Repairs section of Chapter 7 − Chassis).

Remove seat and seat suspension from machine

5

4.

Remove seat plate (item 2) from machine.

5.

Remove thumb screws that secure control panel

(item 25) to fuel tank. Unplug wire harness connections

from panel components and remove panel.

7

6

6.

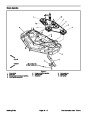

Remove flange head screws and flange nut that se-

cure lower control panel to machine (Fig. 7).

Figure 7

7.

from left fender.

Remove lock nut (item 31) and flat washer (item 32)

1.

Knob

Flange head screw

Choke control

5.

6.

7.

Throttle control

Lift control lever

Flange nut

2.

3.

4.

8.

Use a fuel transfer pump to remove fuel from the fuel

Lower control panel

tank and into a suitable container.

Groundsmaster 3320

Page 3 − 7 Rev. A

Gasoline Engine

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3280 D, Toro Groundsmaster 3320 |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)