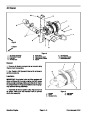

Removal (Fig. 3)

Park machine on a level surface, lower cutting deck

(or implement), stop engine, engage parking brake and

remove key from the ignition switch.

Installation (Fig. 3)

1.

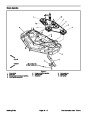

1. Carefully position rear frame and axle assembly to

machine frame.

NOTE: The flange head screws (item 6) used to secure

the rear frame and axle assembly to the machine frame

have a patch lock to prevent the screws from loosening.

When installing rear frame and axle to machine, either

replace flange head screws (item 6) or clean screw

threads and apply Loctite #242 (or equivalent) to

threads of screws.

2.

Block front tires to prevent the machine from moving.

NOTE: To ease reassembly, tag hydraulic hoses to

show their correct position on the steering cylinder.

3.

cylinder. Put caps or plugs on all fittings and hoses to

prevent contamination.

Disconnect the hydraulic hoses from the steering

2.

Align mounting holes in rear frame and axle assem-

bly. Install and tighten four (4) flange head screws (item

to secure rear frame and axle assembly. While tight-

4.

On 4 wheel drive machines, remove six (6) socket

6)

head screws and lock washers that secure drive shaft to

bidirectional clutch. Position drive shaft away from bi-

directional clutch.

ening screws, make sure that mounting holes on the

rear of the frame align with the axle frame holes.

3.

(2)

Secure rear of axle frame to machine frame with two

cap screws and lock nuts.

5.

move weight(s).

If machine has rear weight(s) attached to frame, re-

4.

rear of machine.

If equipped with rear weight(s), attach weight(s) to

6.

cure rear of axle frame to machine frame.

Remove two (2) cap screws and lock nuts that se-

5.

directional clutch. Secure drive shaft to bidirectional

clutch with six (6) socket head screws and lock washers.

On 4 wheel drive machines, position drive shaft to bi-

7.

just off the ground. Support rear of machine frame with

jack stands or appropriate blocking.

Jack up the rear of the machine so that the tires are

6.

and hoses. Correctly connect hydraulic hoses to the

steering cylinder.

Remove all caps and plugs from hydraulic fittings

8.

cure rear frame and axle assembly to machine frame.

Remove four (4) flange head screws (item 6) that se-

9.

machine.

Carefully move rear frame and axle assembly from

7.

Lower machine to the ground.

8.

Check hydraulic fluid level in reservoir (front axle)

and adjust as required (see Traction Unit Operator’s

Manual).

9.

Start engine and check for component interference

as steering wheel is turned from lock to lock.

10.Check

rear wheel toe−in and adjust if necessary (see

Traction Unit Operator’s Manual).

Groundsmaster 3280−D/3320

Page 7 − 9

Chassis

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3280 D, Toro Groundsmaster 3320 |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)