8.

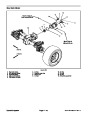

thrust bearing (13), second thrust race (12), and second

retaining ring (3) onto drive shaft (21). Position washer

Place exterior retaining ring (3), thrust race (12),

16.Apply a small amount of petroleum jelly to the steel

side of valve plate (18) to hold in place for installation.

Aligning the index pin, place the valve plate (18) in posi-

tion onto the backplate (20), with steel side against

backplate.

(24)

and shaft seal (25) onto shaft.

9.

Install shaft assembly into front ofhousing. Seat seal

(25)

retaining ring (2).

into position with seal driver and retain with interior

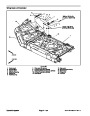

17.Install backplateassembly(20)ontohousingassem-

bly (19). Make sure ports are positioned correctly, and

that valve plate (18) and gasket (32) stay in place.

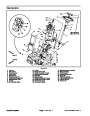

10.Install

servo piston follower (8) onto camplate dowel

pin. Install camplate (11) carefully onto bushing (44)

(coat bushing surface with hydraulic oil), aligning servo

piston follower (8) with slot in servo piston assembly (7).

18.Retain backplate (20) with four cap screws (15).

Torque cap screws from 27 to 31 ft--lb (37 to 42 N--m).

19.Install

control housing gasket (34) onto housing.

11.

Position housing in a horizontal position. Holding

Install orifices (30) into servo control assembly (28) and

retain in position with petroleum jelly. Position the feed-

back link at 90 degrees from control housing. Install

manual servo control assembly (28) onto housing mak-

ingsurefeedback linkenteredsmallgrooveinservopis-

ton assembly (7).

camplate (11) in position with screw driver through con-

troller linkage passageway at the top of housing, place

rotatingkitassembly(6)overshaftandintohousinguntil

pistons are against camplate (11). Make sure all parts

are in housing completely and are properly positioned.

Returnthepumptothevisewithopenendofhousingup,

clamping housing on the outer portion of the flange.

20.Secure

control assembly with six socket head

screws (17). Torque screws from 40 to 48 in--lb (4.5 to

5.4 N--m).

12.Install

gasket (32) onto housing.

13.If

necessary, press new bearing (45) and roll pin (38)

21.Install control arm (27) onto control assembly input

shaft. Retain with lock washer (23) and nut (22). Torque

nut from 4 to 6 ft--lb (5 to 8 N--m).

inbackplate(20)todimensionshowninFigure47.Note:

Bearing should be installed with the numbered end out-

ward. Roll pin should be installed with split oriented

away from bearing.

22.Install

remaining plugs that were removed from

pump. Torque 3/4 in. plug from 21 to 24 ft--lb (28 to 32

N--m). Torque 1--1/4 in. plug from 40 to 45 ft--lb (54 to 61

N--m).

14.Install

relief valve in the cavity in backplate that it was removed

and torque from 100 to 110 ft--lb (136 to 149 N--m).

new o--ring on relief valves (16 & 26). Install

15.Install

new o--ring on bypass valve (14). Install by-

pass valve (14) into backplate (20). Note: Make sure

paddle of bypass valve is perpendicular to relief valve

axis prior to installing or damage could result.

Groundsmaster 4100--D

Page 4 -- 63

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 4100 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)