Removal (Fig. 80)

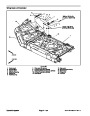

Park machine on a level surface, lower cutting

decks, stop engine, engage parking brake, and remove

key from the ignition switch.

Installation (Fig. 80)

1.

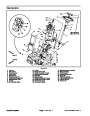

1. If removed, install spherical bearings into lift cylinder

clevis ends.

A. On shaft clevis, press spherical bearing into cle-

vis and secure with retaining ring.

2.

Read the General Precautions for Removing and

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

B. On barrel clevis, install spherical bearing on ta-

pered stud and secure with flange nut. Torqueflange

nut from 100 to 140 in--lb (11.3 to 15.8 N--m). Install

stud with spherical bearing into clevis and secure

with retaining ring.

3.

Remove deck covers as needed to allow access to

lift cylinder hoses and fasteners.

4.

To prevent contamination of hydraulic system during

lift cylinder removal, thoroughly clean exterior of cylin-

der and fittings.

2. Thoroughly clean tapered surfaces of lift cylinder

stud and mounting boss on deck.

NOTE: To ease reassembly, tag the hydraulic hoses to

show their correct position on the lift cylinder.

3. Position lift cylinder to cutting deck. Insert tapered

stud into deck mounting boss. Secure stud with flat

washer and flange nut. Torque flange nut from 160 to

5.

Disconnect hydraulic hoses from lift cylinder.

180

ft--lb (217 to 244 N--m).

6.

cylinder clevis to the wing deck.

Remove cap screw and lock nut that secure the lift

4.

the deck brackets and cylinder shaft clevis. Secure cap

screw withlocknut.Torquelocknutfrom160to180ft--lb

Insert cap screw from the front of the deck through

7.

stud on the barrel end of the lift cylinder.

Remove flange nut and flat washer from the tapered

(217

to 244 N--m).

5.

6.

7.

Attach hydraulic hoses to lift cylinder.

Install any removed deck covers.

8.

Remove lift cylinder from deck assembly.

9.

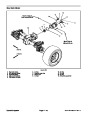

ends, if required.

Remove spherical bearings from lift cylinder clevis

Fillreservoir with hydraulic fluid asrequired (seeOp-

erator’s Manual).

A. On shaft clevis, remove retaining ring and then

press spherical bearing from clevis.

8.

After assembly is completed, operate lift cylinder to

verify that hydraulic hoses and fittings are not contacted

by anything.

B. On barrel clevis, remove retaining ring and then

press tapered stud with spherical bearing and flange

nut from clevis. Remove flange nut and then spheri-

cal bearing from stud.

Groundsmaster 4100--D

Page 4 -- 103

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 4100 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)