3.

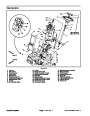

Remove pump from vise, hold pump in hands and

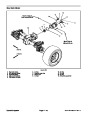

Inspection

bump shaft against wooden block to separate front

pump sections. Front body (10) will remain with either

front plate (15) or front adapter plate (23).

1.

Clean and dry all pump components. Remove nicks

and burrs from all parts with emery cloth.

2.

check for damaged keyway, on drive shaft, that drives

the slip fit gears of the pump.

Check spline drive shaft for damaged teeth. Also

4.

with soft face hammer until the front body separates.

Remove idler gear from front plate or adapter plate.

Place front idler gear (16) into gear pocket and tap

3.

bushing points and seal area for rough surfaces and ex-

cessive wear.

Inspect both the drive gear and idler gear shafts at

5.

Remove plug (8) from front plate (15).

6.

Remove front adapter plate (23) from front body (10)

by tapping on the adapter plate with a soft face hammer.

4.

Replace gear assembly if shaft measures less than

7.

(17).

Remove idler gear (21), slip fit gear (18), and key

.873” (22.17mm) in bushing area. (One gear assembly

may be replaced separately; shafts and gears are avail-

able as assemblies only. The slip fit gear is available

separately).

8.

ping on backplate with soft face hammer.

Remove backplate (27) from rear body (26) by tap-

5.

Inspect gear faces for scoring or excessive wear.

9.

Remove rear idler gear (25), slip fit gear (20) and key

(22).

6. Replace gear assembly if gear width is below

1.181

inch (30.00 mm).

10.Remove

plate (24).

drive gear assembly (11) from rear adapter

7. Assure that snap rings are in grooves on either side

of drive and idler gears.

11.

Place rear idler gear assembly (25) back into gear

pocket and tap protruding end with soft face hammer to

removerearbody(26)fromthebackplateassembly(27)

or the rear adapter plate (24).

8. If any edge of gear teeth is sharp, break edge with

emery cloth.

9.

Oil groove in bushings in front plate, backplate and

IMPORTANT: Note position of the open and closed

side of the wear plates before removing.

adapter plates shouldbein linewith dowelpin holes and

180o apart. This positions the oil grooves closest to re-

spective dowel pin holes.

12.Remove

the wear plates (12) and o--rings (4) from

front plate (15), front adapter plate (23), and rear adapt-

er plate (24).

10.Replace the backplate, front plate or adapter plates

if l.D. of bushings exceed .879” (22.33mm) (Bushings

are not available as separate items).

13.Remove

backup gaskets (14) and pressure seals

(13)

sharp tool.

from wear plates (15) by carefully prying out with a

11.Bushings in front plate and backup gasket side of

adapter plates should be flush with face of plate.

IMPORTANT: Do not damage the seal bore in the

front plate during seal removal.

12.Check for scoring on face of backplate and adapter

plates. Replace if wear exceeds .0015” (.038mm).

14.Remove

plate (15).

shaft seal (1) and washer (2) from front

plug (7) and washer (9) from rear adapter

proportional valve (6) from backplate as-

13.Check bodies inside gear pockets for excessive

scoring or wear.

15.Remove

plate (24).

14.Replace bodies if l.D. of gear pockets exceeds

2.100 inch (53.34mm).

16.Remove

sembly (27).

Groundsmaster 4100--D

Page 4 -- 55

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 4100 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)