3.

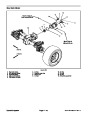

Using an arbor press, push the bearing cups into the

top and bottom of the spindle housing. The top bearing

cup must contact the spacer previously installed, and

the bottom bearing cup must contact the snap ring.

Make sure that the assembly is correct by supporting the

first bearing cup and pressing the second against it (Fig

16).

PRESS

4

4.

grease on lips of oil seals.

Pack the bearing cones with grease. Apply a film of

3

1

2

6

5

5.

Install lower bearing cone and oil seal into bottom of

spindle housing. Note: The lower seal must have the lip

facing out (down) (Fig. 18).

Figure 16

IMPORTANT: If bearings are being replaced, make

sure to use the spacer ring that is included in bear-

ing set.

1.

2.

3.

Bearing cups

Large snap ring

Large outer spacer

4.

5.

6.

Arbor press

Support

Arbor press base

6.

Slide spacer ring and inner bearing spacer into

spindle housing, then install upper bearing cone and oil

seal into top of housing. Note: The upper seal must have

the lip facing in (down) and be recessed into the spindle

housing .095” (2.4 mm) (Fig. 18).

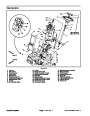

1

4

2

7.

Inspect the spindle shaft and shaft spacer to make

sure they are free of burrs or nicks that could possibly

damage the oil seals. Lubricate the shaft with grease.

5

3

1

8.

Install spindle shaft spacer onto shaft. Carefully slide

spindle shaft with spacer up through spindle housing.

The bottom oil seal and spindle spacer fit together when

the spindle is installed fully.

Figure 17

9.

shaft.

Lightly grease o−ring and install to top of spindle

1.

2.

3.

Bearing

Spacer ring

Large snap ring

4.

5.

Inner spacer

Outer spacer

10.For

drive spindle, position motor mount to top of

spindle assembly.

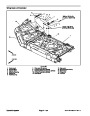

.095”

(2.4 mm)

NOTE: Early production spindle assemblies included a

v−ring seal (item 4) which has been found to be unnec-

essary.Do not install a v−ring seal when assembling the

spindle.

2

11.

Install pulley (hub down), flat washer, and lock nut to

spindle shaft. Tighten lock nut from 130 to 150 ft−lb (176

to 203 N−m).

12.Attach

a hand pump grease gun to grease fitting on

housing and fill housing cavity with grease until grease

starts to come out of lower seal. Note: Pneumatic

grease guns can produce air pockets when filling large

cavities and therefore, are not recommended to be used

for proper greasing of spindle housings.

1

13.Rotate

spindle shaft to make sure that it turns freely.

Figure 18

1.

Bottom seal installation

2.

Upper seal installation

Groundsmaster 4100−D

Page 8 − 17 Rev. E

Cutting Deck

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 4100 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)