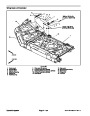

E. Thoroughly clean tapered surfaces of stud and

mounting boss of support hub. Secure support hub

(position slotted hole in hub toward rear of deck) to

tapered stud with flat washer and flange nut. Tighten

flange nut from 155 to 185 ft−lb (210 to 321 N−m).

CAUTION

When raising machine, use correct blocks,

hoists, and jacks. Make sure machine is parked

on a solid, level surface such as a concrete

floor. Prior to raising machine, remove any at-

tachments that may interfere with the safe and

proper raising of the machine. Always chock or

block wheels. Use jack stands or solid wood

blocks to support the raised machine. If the ma-

chine is not properly supported by blocks or

jack stands, the machine may move or fall,

which may result in personal injury.

2.

Position lift arm to frame and insert lift arm pin. En-

gage roll pin into frame slots and install lock nut on pin.

Torque lock nut from 60 to 70 ft−lb (81 to 94 N−m).

3.

Align lift cylinder with lift arm. Slide lift cylinder pin

through lift arm and cylinder end. Secure pin with flange

head screw and lock nut.

4.

Install front wheel assembly. Lower machine to the

ground.

3.

Support machine on jack stands. Remove front wheel

next to lift arm that is being removed.

Chock rear wheels and jack up front of machine.

5.

Chapter 8 − Cutting Deck).

Install cutting deck (see Cutting Deck Installation in

6.

Manual).

Lubricate lift arm grease fittings (see Operator’s

4.

lift cylinder pin to lift arm. Remove pin and separate lift

cylinder from lift arm.

Remove flange head screw and lock nut that secure

7.

After assembly is completed, raise and lower the cut-

ting deck to verify that hydraulic hoses and fittings do not

contact anything.

5.

arm and slide pin from frame and lift arm. Remove lift

arm from frame.

Remove lock nut that secures lift arm pin. Support lift

8.

Check height−of−cut and deck pitch adjustment (see

Operator’s Manual).

6.

As needed, disassemble lift arm:

A. Remove height−of−cut chain and damper as-

sembly.

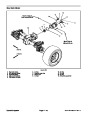

.750”

(19.1 mm)

2

B. Press flange bearings from lift arm.

C. Remove flange nut, flat washer, and support hub

from tapered stud. Remove tapered stud with spheri-

cal bearing from lift arm after removing retaining ring

from lift arm. Remove flange nut and spherical bear-

ing from stud.

1

Figure 3

Installation

1.

Lift arm

2.

U−bolt threads

1.

If removed, install components to lift arm.

A. Assemble height−of−cut chain u−bolt so that

threaded portion of u−bolt extends .750” (19.1 mm)

above mounting plate on lift arm (Fig. 3).

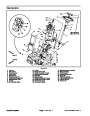

2

B. If rod ends were removed from damper, apply

Loctite #242 to threads and install on damper. Install

damper assembly to lift arm with damper rod end to-

ward deck (Fig. 4).

4

3

C. Press flange bearings into lift arm.

1

D. Install spherical bearing on tapered stud and se-

cure with flange nut. Torque flange nut from 100 to

140

cal bearing into lift arm and secure with retaining ring.

in−lb (11.3 to 15.8 N−m). Install stud with spheri-

Figure 4

1.

2.

Lift arm

Deck castor arm

3.

4.

Support hub

Damper

Groundsmaster 4100−D

Page 7 − 5

Chassis

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 4100 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)