6.

Support wing deck to prevent it from falling as links

are removed.

3

7.

Remove cap screw and washer from pivot pin on up-

per end of both links. Remove flange nut from carriage

bolt and pull pivot pins from deck. Locate and retrieve

two thrust washers (item 6) from upper end of both links

and two hardened spacers (item 42) from front link.

2

8.

Slide the wing deck away from the center deck.

9.

If required, remove link(s) from wing deck by remov-

2

1

ing flange nut and flat washer that secure tapered stud

to deck. Press tapered stud from deck to remove link as-

sembly.

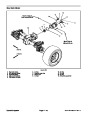

Figure 7

1.

2.

Hydraulic motor

Flange head screw

3.

Lift cylinder clevis

Installation (Fig. 6)

1.

Park machine on a clean, level surface. Stop engine,

engage parking brake, and remove key from the ignition

switch.

2.

If links were removed from wing deck, thoroughly

clean tapered stud on link and mounting boss of wing

deck. Insert tapered stud into deck mounting boss and

secure with flat washer and flange nut. Torque flange nut

from 160 to 180 ft−lb (217 to 244 N−m).

.380”

(9.7 to 15.7 mm)

to .620”

1

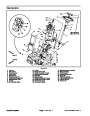

3.

Position the wing deck to the center deck.

2

NOTE: If two thrust washers (item 6) cause front link to

bind, use only one thrust washer on rear side of front

link.

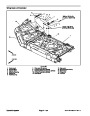

Figure 8

1.

Wing deck blade

2.

Center deck blade

4.

Position thrust washers (item 6) to upper end of links.

9.

ponents (see Operator’s Manual).

Lubricate grease fittings on cutting deck and lift com-

Front link has both thrust washers toward the rear. Rear

link has thrust washer on each side. Also, place hard-

ened spacer (item 42) on each side of front link. Align up-

per end of links with mounting holes in center deck.

Install pivot pins.

10.Check

distance between inner deck blade on wing

deck and outer deck blade on center deck. Distance be-

tween blades should be .380” to .620” (9.7 to 15.7 mm)

(Fig. 8). If blade distance is incorrect, loosen hex jam nut

(item 32) on rear link assembly and adjust cap screw

(item 31). Tighten jam nut when blade distance is cor-

rect.

5.

and flange head screw. Install washer and cap screw to

pivot pins.

Secure pivot pins to center deck with carriage screw

6.

cylinder with cap screw and lock nut.

Position lift cylinder to the wing deck (Fig. 7). Secure

11.

locked when wing deck is in the lowered position.

Inspect deck latch assembly to insure that link is

7.

Deck Motor Installation in the Service and Repairs Sec-

tion of Chapter 4 − Hydraulic Systems).

Install hydraulic motor to cutting deck (see Cutting

12.Check

if necessary (see Wing Deck Position Switches in the

Adjustments section of Chapter 5 − Electrical System).

operation of wing deck position switch. Adjust

8.

Fully raise wing deck, stop engine, and remove key

from the ignition switch. Secure flex shield to wing deck

with shield strap and three (3) washer head screws.

Lower wing deck.

Groundsmaster 4100−D

Page 8 − 11 Rev. C

Cutting Deck

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 4100 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)