6.

7.

just plug until there is no end play in the valve spool with

input shaft held stationary. Secure plug in place with set

screw (24). Torque set screw from 17 to 26 in--lb (2 to 3

N--m).

Install wiper seal on input shaft.

5. Test the switch by moving the control arm to the det-

entposition,thelightshouldbeon.Movethecontrolarm

out of detent, the light should go off.

Install new o--ring (2) onto plug and install plug. Ad-

6. Remove test light and put servo control assembly

into operation.

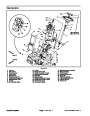

Disassembly -- Neutral Switch

Reassembly

“A”

Step 4--C

1.

Loosensetscrew(17)inadapterandremoveneutral

switch from adapter.

2.

Remove adapter from control housing.

3.

Remove pin, ball, and o--rings (11 & 16) from adapt-

er.

Reassembly -- Neutral Switch

Install new o--ring (11) onto adapter and new o--ring

Reassembly

Step 4--D

“B”

“B”

1.

(16)

onto pin.

2.

leum jelly to hold in place during installation.

Install ball and pin into adapter. Lubricate with petro-

3.

Install adapter into control housing. Torque from 44

to 52 ft--lb (60 to 70 N--m).

4.

switch and install switch into adapter. The adjustment

procedure for the switch are as follows.

Apply Loctite#222orequivalenttothreads ofneutral

Reassembly

Step 4--E

A. Install switch, while moving link back and forth,

until “detent” action is detected. Back out the switch

until the “detent” action is very slight.

B. Attach the leads from a test light to the switch ter-

minals. Note: A multimeter could be used instead of

a test light.

“A”

C. Move the link out of the detent position. The test

light will go on (continuity). Screw in the switch until

thelightgoesoff(nocontinuity).Markthisasposition

“A” (Fig. 52). Move the link to the detent position and

the test light should come back on.

Figure 52

D. Leavingthelinkinthedetentposition,thelightwill

remain on.Screw in the switch until the light goes off.

Mark this position “B”.

E. Unscrew the switch one third of the distance be-

tween “B” and “A”. Install and tighten the set screw

(17)

in one of the upper quadrants of the hex of the

switch adapter (Fig. 52). Torque set screw from 28 to

in--lb (3.2 to 3.8 N--m).

34

Groundsmaster 4100--D

Page 4 -- 65

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 4100 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)