6.

Set the bearing preload by securing the bearing case

in a vise. Thread a M12 x 1.5 hex head cap screw into

the splined end of the input shaft/pinion gear and slowly

tighten the locknut until 4 to 6 in-lb (0.4 to 0.7 N−m) of

force is required to rotate the input shaft/pinion gear in

the bearing case.

0.040

in. (1.0 mm)

7.

8.

Secure the lock nut with the stake washer.

1

2

Use a depth gauge to measure the distance from the

end face of the input shaft/pinion gear to the mating sur-

face of the bearing case. Subtract the “Design Cone

Center Distance” from this distance to determine initial

shim thickness (Fig. 30).

3

DESIGN CONE CENTER DISTANCE (distance

from mating surface of axle support to end face of

pinion gear):

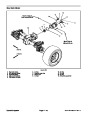

Figure 29

3.

1.

2.

Oil seal

Bearing case

Seal garter spring

1.870

+ 0.002 in. (47.5 + 0.05 mm)

NOTE: Bearing case shims are available in 0.004 in.

(0.1 mm) and 0.008 in. (0.2 mm) thickness.

9.

Coat new O-rings with grease and install the bearing

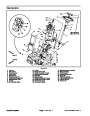

1

Design

Cone Center

Distance

case in the gear case. Place shims on the gear case and

temporarily install gear case assembly into axle case.

Tighten mounting nuts and screws from 35 to 41 ft-lb (47

to 56 N−m).

10.Insert

a screwdriver through the drain plug hole to

hold ring gear and measure the pinion gear to ring gear

backlash (Fig. 31).

2

PINION GEAR TO RING GEAR BACKLASH:

0.004

to 0.016 in. (0.10 to 0.40 mm)

Figure 30

11.

shim thickness.

Adjust backlash by increasing or reducing gear case

1.

Input shaft/pinion gear

2.

Bearing case

12.Check

pinion gear to ring gear engagement (see Pin-

ion Gear to Ring Gear Engagement in this section of this

manual).

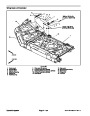

1

13.Place

the correct combination of shims on the gear

case. Tighten mounting nuts and screws from 35 to 41

ft-lb (47 to 56 N−m).

3

2

14.Install

retaining rings and driven gear on input shaft/

pinion gear.

15.If

the drive gear (on drive motor shaft) was removed,

4

install the retaining rings and drive gear on the motor

shaft.

16.Use

new O-ring and install the drive motor.

a new gasket and install the cover plate. Use a

Figure 31

3.

4.

1.

2.

Axle case

Screwdriver

Dial indicator

Input shaft/pinion gear

Groundsmaster 4100−D

Page 6 − 23

Axles, Planetaries, and Brakes

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 4100 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)