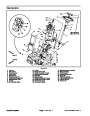

Disassembly (Fig. 74)

Assembly (Fig. 74)

1.

Plug all ports and clean outside of valve thoroughly.

1. Thoroughlycleananddryallparts.Applyalightcoat-

ing of clean hydraulic oil to parts prior to assembly.

2.

Remove spool caps (9). Do not remove retaining

rings (12) from spools unless spool spring (19) is bro-

ken.

NOTE: AllO--rings,back--upwashers, wiper seals,and

nylon poppets should be replaced as new items.

NOTE: Spools and spool bores are matched sets. Be

sure each spool is identified with the correct valve body

spool bore.

2. Install new O--rings (11) in proper grooves in spool

bores.

3.

Install relief valve components (13, 14, 15, 31, and

3.

4.

5.

Remove spools (35) from valve body (36).

Remove bushings (8) and O--rings (11) from spools.

Remove plugs (6).

10) with new O--ring (34) on plug assembly (32).

4. Install plugs (6) with new back--up washers (20) and

O--rings (7).

5.

Install plungers (33 and 28).

IMPORTANT: Check location and positioning of

plungers when removing from body to assure prop-

er assembly.

IMPORTANT: Check location and positioning of

plungers during installation.

6.

(1),

Remove plugs (29), lockout springs (30), poppets

seats (4) and plungers (28 and 33).

6. Install new O--rings (5) on seats (4). Install new

back--up washers (26) and O--rings (25) on plugs (29).

7.

8.

Remove plug (17).

7. Install seats (4), new poppets (1), and plugs (29).

8. Install plug (17) with new O--ring (18).

Remove detent plug (23), disc (27), detent spring

and detent plunger (22).

(21)

9.

Install detent plunger (22), spring (21), disc (27), and

9.

and 15), relief valve spring (31), and relief valve poppet

(10).

Remove relief plug assembly (32), washers (13, 14,

plug (23) with new O--ring (24).

10.If

retaining ring (12) has been removed to replace

spool spring (19), install washer (16), spring (19), and

spacer (2) on spool. Secure with retaining ring (12).

10.Remove

and seats.

allO--ringsandback--upringsfromallplugs

11.

Slide bushings (8) over spools. Slide new O--rings

Inspection

(11) over spools and position next to bushings. Dip

spoolsincleanhydraulicoilandinstallspoolassemblies

into proper location of valve body.

1.

Remove all nicks and burns from parts and inspect

for excessive wear.

12.Install

(27

spool caps (9) and tighten from 20 to 25 ft--lb

to 33 N--m).

new wiper seals (3).

2.

roughness.

Inspect all plungers and poppet seats for burrs or

13.Install

3.

Inspect spool springs (19), relief valve spring (31),

lockout springs (30), and detent spring (21) for break-

age.

4.

If spools (35) have excessive wear, the control valve

becomes non--serviceable as the spools and spool

bores are matched. Damaged spools cannot be re-

placed individually.

5.

Inspectreliefvalvepoppet(10) forbreakage orwear.

Groundsmaster 4100--D

Page 4 -- 93

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 4100 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)