Mow Circuit

Hydraulic flow for themow circuit is supplied by twosec-

tions of the gear pump. The gear pump section closest

to the piston (traction) pump supplies hydraulic flow to

the wing decks, while the next gear pump section sup-

plies the center deck.

TO DECK

MOTOR

PUMP FLOW

Each cutting deck is controlled by a hydraulic manifold

equipped with a solenoid control valve (SV1), bypass

cartridge (BY1), brake cartridge (BR1), and relief car-

tridge (R1BR). When the the deck solenoid valve (SV1)

is not energized (PTO switch OFF), hydraulic flow by--

passes the deck motor through the bypass cartridge

(BY1). When the PTO switch is turned ON, the solenoid

valve (SV1) energizes, causing a shift of the by--pass

cartridge (BY1) and allowing hydraulic flow to the deck

motor. Brake cartridge (BR1) and relief cartridge

(R1BR) control the stopping rate of the blade when the

solenoid control valve is de--energized as the PTO

switch is turned OFF.

FROM DECK

MOTOR

RETURN

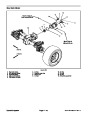

Figure 9

TO DECK

MOTOR

Thesolenoidvalve(SV1)foreachwingdeckisde--ener-

gized any time the wing deck is raised.

PUMP FLOW

Returnoilfromthedeckmotorsisdirectedtotheoilcool-

er and oil filter. Deck motor case drain leakage returns

to the hydraulic reservoir.

Maximum mow circuit pressure is limited at each deck

by a relief valve (R1BY) in the hydraulic manifold. The

center and left wing deck relief valves are set at 3000

PSI and the right wing deck relief valve is set at 2000

PSI.

FROM DECK

MOTOR

RETURN

Circuit pressure can be measured at port (G) of the hy-

draulic manifold for each cutting deck.

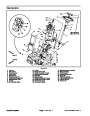

Figure 10

Cutting Deck Blade Braking

When the operator turns the cutting deck OFF, solenoid

valve (SV1) is de--energized causing logic cartridge

(BY1) to shift (Fig. 9). This shifted valve allows oil return

totheoilcoolerandgearpump.Hydraulicpressureisre-

ducedtothecuttingdeckmotorwhichbeginstoslowthe

cutting blades and also causes logic cartridge (BR1) to

shift (Fig. 10).

TO DECK

MOTOR

PUMP FLOW

FROM DECK

MOTOR

The inertia of the rotating cutting blades increases pres-

sure of the oil return to the deck control manifold. This

pressure increase, along with the shifted logic cartridge

(BR1), causes relief valve (R1BR) to shift, which bleeds

the residual pressure in the circuit and allows the blades

to stop in a controlled manner (Fig. 11).

RETURN

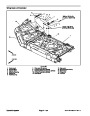

Figure 11

Groundsmaster 4100--D

Page 4 -- 15 Rev. E

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 4100 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)