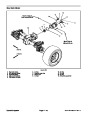

Planetary Wheel Drive Disassembly (Figure 7)

Planetary Wheel Drive Assembly (Figure 7)

1.

2.

Remove retaining ring (12).

NOTE: Use new seal kit when assembling planetary

wheel drive.

Remove end cap (14). Thrust plug (15) and thrust

washer (16) are captive on inside of end cap.

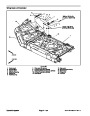

1. Clean parts in solvent. Inspect parts for damage or

excessive wear and replace as necessary.

3.

4.

Remove drive shaft (17).

2.

If spindle and housing were separated:

A. Install boot seal (2) to spindle (1).

Remove carrier assembly (18).

NOTE: Steps 6 −10 are necessary only if inspecting or

replacing bearings and/or seals.

B. Press bearing cups (4 and 7) into housing (6).

C. Install bearing cone (3) onto spindle (1).

5.

Remove socket head screws (19) with lock washers

and remove ring gear (11).

(20)

D. Install seal (24) to housing (6). Assemble housing

(6) to spindle (1).

6.

Remove retaining ring (10) and thrust washer (9).

7.

ing cone (8).

Remove spindle (1) from housing (6). Remove bear-

E. Install bearing cone (8) onto spindle and secure

with thrust washer (9) and retaining ring (10).

8.

Remove and discard all seals.

F. After retaining ring is installed, make sure that

there is minimal endplay in assembly. If required,

thrust washer options are identified in the parts

manual.

9.

from spindle. Remove bearing cups (4 and 7) from hous-

ing (6).

If bearings will be replaced, remove bearing cone (3)

G. Install o−ring (21) and then assemble ring gear

(11)

to housing (6) with lock washers (20) and socket

head screws (19). Torque socket head screws to 9 ft−

lb (12 N−m).

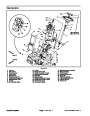

3.

4.

5.

6.

Install carrier assembly (18).

Install drive shaft (17).

Install thrust washer (16) and thrust plug (15).

Make sure that thrust plug (15) and thrust washer

(16)

are captive on inside of end cap. Install o−ring (22)

to end cap and then install end cap (14). Secure cap with

retaining ring (12).

7.

Check operation of planetary wheel drive before

installing assembly on the machine. With a constant

turning force applied, rotation of the planetary should be

consistent. If there is more drag at certain points, gears

are not rolling freely and the planetary should be ex-

amined for improper assembly or damaged compo-

nents.

Groundsmaster 4100−D

Page 6 − 11

Axles, Planetaries, and Brakes

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 4100 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)