Procedure for Steering and Lift/Lower Gear Pump

Flow Test

8. If the total of the two flows is lower than 7 GPM or a

pressure of 1000 PSI could not be obtained, check for

restriction in pump intake line. If intake line is not re-

stricted, remove gear pump and repair or replace as

necessary.

Output from the steering and lift/lower gear pump sec-

tion is equally divided by a proportional valve to provide

flow to the steering circuit and the lift circuit. To test gear

pump flow, testing of both steering and lift/lower circuits

is required. Total gear pump flow is the combined flow

from the two circuits.

Ifthe total ofthe two flows is 7 GPM but individual circuit

flow is less than 3.5 GPM (e.g. steering circuit has 2

GPM and lift circuit has 5 GPM), suspect a problem with

the proportional valve in the gear pump.

1.

Make sure hydraulic oil is at normal operating tem-

perature by operating the machine for approximately 10

minutes. Make sure the hydraulic tank is full.

2.

decks lowered and off. Make sure engine is off and the

parking brake is engaged. Raise seat.

Park machine on a level surface with the cutting

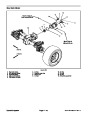

2

1

3

CAUTION

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS, and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

Figure 34

3.

IMPORTANT: Make sure that the oil flow indicator

arrow on the flow gauge is showing that the oil will

flow from the pump, through the tester, and into the

hydraulic hose.

1.

2.

Hydraulic tank cap

Lift circuit hose

Steering circuit hose

3.

With the engine off and cutting decks lowered, install

1

2

3

tester with pressure gauges and flow meter in series be-

tween the last gear pump section and one of the circuit

hoses (Fig. 34). Make sure the tester flow control

valve is open.

4.

speed. Check for hydraulic leakage and correct before

proceeding with test.

After installing tester, start engine and run at idle

4

IMPORTANT: The pump is a positive displacement

type. If pump flow is completely restricted or

stopped, damage to the pump, tester, or other com-

ponents could occur.

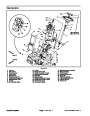

Figure 35

1.

2.

Gear pump backplate

Lift circuit

3.

4.

Steering circuit

Proportional valve

5.

Operate the engine at full speed (2730 + 30 RPM).

DO NOT engage the cutting decks.

6.

flowcontrolvalveonthetesteruntil1000PSIisobtained

While watching tester pressure gauges, slowly close

on gauge. Verify engine speed continues to be correct

(2730

+ 30 RPM). Record test results.

GAUGE READING TO BE: Flow approximately 3.5

GPM at 1000 PSI.

7.

move tester and reinstall disconnected hose. Complete

steps 3 through 6 for other circuit hose.

Open tester flow control valve and stop engine. Re-

Groundsmaster 4100--D

Page 4 -- 41

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 4100 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)