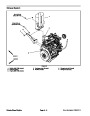

Removal (Fig. 106)

5. Remove plugs that were installed in hydraulic hoses

during the removal procedure. Correctly connect hy-

draulic hoses to lift cylinder fittings using labels placed

during lift cylinder removal (see Hydraulic Hose and

Tube Installation in the General Information section of

this chapter).

WARNING

Before disconnecting or performing any work on

the hydraulic system, all pressure in the system

must be relieved. See Relieving Hydraulic System

Pressure in the General Information section.

6. Lubricate grease fittings on lift cylinder and pivot pin.

7.

Make sure hydraulic tank is full. Add correct oil if nec-

essary.

1.

Park machine on a level surface, lower cutting deck

(or implement), stop engine, engage parking brake and

remove key from the ignition switch.

2

2.

Thoroughly clean hydraulic hose ends and fittings on

lift cylinder to prevent hydraulic system contamination.

3.

label orientation of hydraulic hose at barrel end of lift cyl-

inder to allow correct assembly.

Label hydraulic hoses for assembly purposes. Also,

4.

draulic fittings on the lift cylinder. Install clean plugs in

hose openings to prevent system contamination.

Disconnect hydraulic hoses connected to the hy-

1

5.

Remove retaining ring that secures lift cylinder barrel

end to pin on carrier frame.

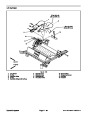

Figure 107

1.

Lift cylinder

2.

Pivot pin

6.

Remove flange head screw and pivot pin that secure

lift cylinder rod end to RH lift arm (Fig. 107).

7.

8.

Remove lift cylinder from machine.

If necessary, remove hydraulic fittings from lift cylin-

der. Remove and discard O–rings from fittings. Note that

fitting on barrel end of cylinder is an orifice fitting that is

different than fitting on rod end of cylinder.

Installation (Fig. 106)

1.

If hydraulic fittings were removed from lift cylinder, lu-

bricate and install new O–rings to fittings. Install fittings

into lift cylinder ports and torque fittings from 15 to 19 ft–

lb (20 to 25 N–m). Make sure that fitting on barrel end

of cylinder is the orifice fitting.

2.

Position lift cylinder to the machine.

3.

Secure cylinder barrel end to pin on carrier frame

with retaining ring.

4.

Secure cylinder rod end to RH lift arm with pivot pin

and flange head screw (Fig. 107).

Groundsmaster 7200/7210

Page 4 – 93

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 7200, Toro Groundsmaster 7210 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)

My mower is a TORO 7210.

Start fuse defection. Why ?