Oil Cooler

Removal (Figs. 111 and 112)

2. Lubricate and place new O–rings in oil cooler ports.

Remove plugs from hydraulic hoses. Connect hydraulic

hoses to oil cooler using labels placed during removal

(see Hydraulic Hose and Tube Installation in the Gener-

al Information section of this chapter).

1.

Park machine on a level surface, lower cutting deck

(or implement), stop engine, engage parking brake and

remove key from the ignition switch.

2.

Raise hood and secure it in the raised position.

3.

Make sure hydraulic tank is full. Add correct oil if nec-

essary.

CAUTION

4.

Lower and latch hood.

The radiator and oil cooler may be hot. To avoid

possible burns, allow the engine and cooling

systems to cool before working on the oil cooler.

2

3.

Thoroughly clean hydraulic hose ends and oil cooler

fittings to prevent hydraulic system contamination. La-

bel hydraulic hoses for assembly purposes.

4.

Remove hydraulic hoses from oil cooler. Install clean

plugs in hose openings to prevent contamination. Re-

move and discard O–rings from oil cooler fittings.

1

5.

Rotate clamp and tilt oil cooler from radiator frame.

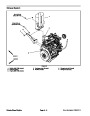

Figure 111

Slide left side of oil cooler from radiator frame by aligning

roll pin in cooler mount with slot in radiator frame. Then,

remove right side of cooler from radiator frame.

1.

Oil cooler

2.

Clamp

4

Inspection

RIGHT

3

2

1.

Back flush oil cooler with cleaning solvent. Make

sure all solvent is drained from the cooler.

FRONT

1

2

5

CAUTION

6

7

Use eye protection such as goggles when using

compressed air to dry oil cooler.

8

2.

opposite direction of the oil flow.

Dry inside of oil cooler using compressed air in the

9

3.

clean exterior of cooler.

Install clean plugs on oil cooler ports. Thoroughly

10

4.

tubes or excessive pitting of tubes.

The oil cooler should be free of corrosion, cracked

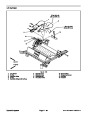

Figure 112

1.

Oil cooler

Flange nut

Washer

Cap screw

Clamp

6.

7.

8.

9.

Roll pin

2.

3.

4.

5.

O–ring (2 used)

Hydraulic hose

Hydraulic hose

Installation (Figs. 111 and 112)

10. Radiator frame

1.

Install right side mount of oil cooler through hole in

radiator frame. Then, slide left side cooler mount into ra-

diator frame by aligning roll pin and slotted hole in radia-

tor frame. Tilt cooler to radiator frame and secure with

clamp.

Hydraulic System

Page 4 – 100

Groundsmaster 7200/7210

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 7200, Toro Groundsmaster 7210 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)

My mower is a TORO 7210.

Start fuse defection. Why ?