The Lift Cylinder Internal Leakage Test should be per-

formed if a cutting deck (or implement) raise and lower

problem is identified. This test will determine if the lift cyl-

inder is faulty.

B. Rod movement in excess of 1/4” (6.4 mm) after 4

hours indicates a lift cylinder with internal seal dam-

age or excessive internal wear. Replace or repair the

lift cylinder (see Lift Cylinder and Lift Cylinder Ser-

vice in the Service and Repairs section of this chap-

ter).

NOTE: Raise/lower circuit operation will be affected by

lift cylinder binding, extra weight on the cutting deck (or

implement) and/or binding of lift components. Make

sure that these items are checked before proceeding

with the lift cylinder internal leakage test.

8. Once lift cylinder condition has been determined,

use a jack to raise both sides of the cutting deck (or im-

plement) slightly which will remove the load from the lift

cylinder. Support both sides of the cutting deck (or im-

plement) with jack stands. Remove the cap from the cyl-

inder fitting and the plug from the hydraulic hose.

Connect the hydraulic hose to the lift cylinder fitting.

Procedure for Lift Cylinder Internal Leakage Test:

1.

Park machine on a level surface with the PTO switch

OFF. Position the cutting deck (or implement) in a par-

tially raised position and turn the engine off. Apply the

parking brake.

9.

Remove tape from lift cylinder rod.

the jack stands from under the cutting deck

10.Remove

2.

Under both sides of the cutting deck (or implement),

(or implement). Start engine and operate lift cylinder

through several raise and lower cycles. Stop the engine

and check for any leakage.

use a jack to raise the cutting deck (or implement) slight-

ly. This will remove the load from the lift cylinder and re-

lieve lift cylinder hydraulic pressure. Support both sides

of the cutting deck (or implement) with jack stands to

prevent the lift cylinder from retracting.

11.Check oil level in hydraulic reservoir.

3.

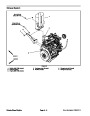

Thoroughly clean the area around the hydraulic hose

end at the barrel end of the lift cylinder. Disconnect the

hydraulic hose from the lift cylinder barrel end fitting

(Fig. 27).

2

IMPORTANT: When capping the lift cylinder fitting

and hydraulic hose end, use a steel cap and plug to

ensure that fluid leakage will not occur. Plastic

plugs will not hold hydraulic pressure that will be

developed during this test procedure.

4.

Place a steel cap on the open lift cylinder fitting to

seal the lift cylinder. Also, install a steel plug in the open

end of the disconnected hose to prevent leakage or con-

tamination.

1

Figure 27

5.

Remove the jack stands from under the cutting deck

1.

Lift cylinder

2.

Barrel end hose

(or implement). The cutting deck (or implement) should

settle slightly and then be supported by the capped lift

cylinder.

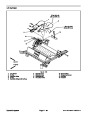

MEASURED

DISTANCE

1

2

6.

Place a piece of tape on the lift cylinder rod near the

rod end (Fig. 28). Measure and record the distance from

the lift cylinder collar to the tape location.

7.

Leave the machine parked for 4 hours and monitor

the lift cylinder. The weight of the cutting deck (or imple-

ment) will cause the lift cylinder to gradually retract. Use

the change in distance from the lift cylinder collar to the

tape location to determine lift cylinder rod movement.

Figure 28

1.

Lift cylinder collar

2.

Tape

A. If the cutting deck (or implement) is still sus-

pended after 4 hours and lift cylinder rod movement

is less than 1/4” (6.4 mm), consider that the lift cylin-

der is in good condition. A lift cylinder in good, usable

condition will show minimal rod movement.

Groundsmaster 7200/7210

Page 4 – 41

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 7200, Toro Groundsmaster 7210 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)

My mower is a TORO 7210.

Start fuse defection. Why ?