6.

Disconnect both battery cables at the battery. Dis-

3

connect negative cable first and then positive cable (see

Battery Service in the Service and Repairs section of

Chapter 5 – Electrical System).

7.

Remove muffler from the engine (see Muffler Re-

moval in this section).

8.

moval in this section). Remove fan shroud.

Remove radiator from machine (see Radiator Re-

2

4

9.

Label all electrical wires for assembly purposes. Dis-

connect electrical wires from engine:

A. Negative battery cable, wire harness ground and

fuel stop solenoid (Fig. 11).

1

B. Glow plug bus (Fig. 12).

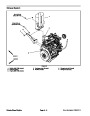

Figure 10

1.

2.

Machine frame

Rear panel

3.

4.

Flange screw (6 used)

Clip (6 used)

C. High temperature warning switch and high tem-

perature shutdown switch (Fig. 13).

D. Starter motor, fusible link harness, alternator and

oil pressure switch.

2

3

10.Disconnect

throttle cable from the throttle support

bracket and swivel on the speed control lever. Position

cable away from engine.

4

11.

11).

Disconnect fuel supply hose at injector pump (Fig.

Disconnect return fuel hose from front injector

nozzle (Fig. 12). Plug and position disconnected hoses

to prevent fuel leakage.

5

1

12.Note

location of cable ties securing the wire harness

to engine. Remove cable ties.

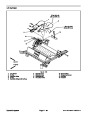

Figure 11

4.

5.

13.Support

transmission to prevent it from moving dur-

1.

2.

3.

Fuel/water separator

Fuel supply hose

Fuel stop solenoid

Fuel hose from pump

Ground connections

ing engine removal.

CAUTION

1

When removing engine assembly, make sure lift

or hoist can safely support 250 pounds (114 kg).

2

3

14.Attach

rear of engine. Support engine with lift or hoist to prevent

engine from shifting or moving.

a suitable lift or hoist to lift tabs on front and

15.Remove

two (2) flange head screws that secure fuel/

water separator bracket to engine. Remove bracket and

separator from engine.

Figure 12

16.Remove

et head screws securing the flywheel housing to engine.

six (6) flange head screws and two (2) sock-

1.

2.

Glow plug wire

Front injector nozzle

3.

Return fuel hose

17.Remove

lock nut, snubbing washer and cap screw

that secures each side of engine to the engine mounts

attached to the frame.

Groundsmaster 7200/7210

Page 3 – 15

Kubota Diesel Engine

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 7200, Toro Groundsmaster 7210 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)

My mower is a TORO 7210.

Start fuse defection. Why ?