The Wheel Motor Efficiency Test should be performed

if a traction circuit problem is identified. This test will de-

termine if a wheel motor has excessive internal leakage

and wear.

8. Install hydraulic tester (pressure and flow) in series

between the pump outlet fitting and the disconnected

hose. Make sure that the tester flow arrow points from

the pump outlet and toward the hose. Make sure the

flow control valve on the tester is fully open.

NOTE: Over a period of time, a wheel motor can wear

internally. A worn motor may by–pass oil to its case drain

causing the motor to be less efficient. Eventually,

enough oil loss will cause the wheel motor to stall under

heavy load conditions. Continued operation with a worn,

inefficient motor can generate excessive heat, cause

damage to seals and other components in the hydraulic

system and affect overall machine performance.

9. Start engine and run at low idle speed (1500 to 1650

RPM). Check for any hydraulic leakage from test con-

nections and correct before proceeding with test.

IMPORTANT: Do not run engine at full speed when

performing this test using Toro Hydraulic Tester

(Pressure and Flow) (TOR214678). Traction pump

output at full engine speed can damage hydraulic

tester.

Procedure for Wheel Motor Efficiency Test:

1.

perature. Also, make sure that traction drive is correctly

adjusted for the neutral position.

Make sure hydraulic oil is at normal operating tem-

10.Using a phototac to measure engine speed, move

throttle so engine speed is 2800 RPM (not full speed).

Make sure parking brake is applied to keep wheel from

rotating during test.

WARNING

CAUTION

Before disconnecting or performing any work on

the hydraulic system, all pressure in the system

must be relieved. See Relieving Hydraulic System

Pressure in the General Information section.

Use extreme caution when performing test. The

rear wheel that is being tested will be trying to

move the machine forward.

2.

(or implement) lowered and off. Apply parking brake and

make sure engine is off.

Park machine on a level surface with the cutting deck

11.

While sitting in operator seat, slowly push traction

control lever for wheel motor being tested in the forward

direction until 1000 PSI (69 bar) is displayed on the test-

er pressure gauge.

3.

Read Precautions for Hydraulic Testing listed at the

beginning of this section.

12.Wheel

motor internal leakage will be shown on the

tester flow meter in GPM (LPM).

4.

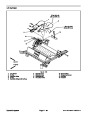

Attach a heavy chain to the rear of the machine frame

and an immovable object to prevent the machine from

moving during testing. As an alternative, machine can

be raised and supported with jack stands so that both

rear wheels are off the ground.

13.Return

traction control lever to the neutral position.

Shut off engine and record test results. Rotate wheel

and retest. Testing of wheel motor leakage in three (3)

different wheel positions will provide the most accurate

test results.

5.

Disconnect wire harness connector from parking

brake switch (see Parking Brake Switch in the Compo-

nents section of Chapter 5 – Electrical System). Install

jumper wire across harness connector terminals to al-

low traction circuit operation with the parking brake ap-

plied.

14.Flow

tested wheel motor. If specification is not met, the

tested wheel motor needs to be repaired or replaced.

should be less than 1.5 GPM (5.7 LPM) for the

15.Relieve hydraulic system pressure (see Relieving

Hydraulic System Pressure in the General Information

section). Disconnect tester from pump outlet fitting and

hydraulic hose. Connect hose to pump fitting.

6.

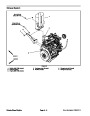

Thoroughly clean transmission area surrounding

traction circuit hoses on top of transmission (Fig. 18).

Determine which wheel motor is to be tested.

16.If

other wheel motor requires testing, complete steps

7.

outlet fitting for wheel motor to be tested (Fig. 18):

Disconnect hydraulic hose from transmission pump

6

to 15 for the remaining motor.

17.After

testing is completed, remove jumper wire from

parking brake harness connector. Connect wire harness

to parking brake switch (see Parking Brake Switch in the

Components section of Chapter 5 – Electrical System).

Make sure that brake switch operation is correct.

Wheel Motor to be Tested

Right Side Motor

Pump Outlet

Port A

Left Side Motor

Port C

Groundsmaster 7200/7210

Page 4 – 33

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 7200, Toro Groundsmaster 7210 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)

My mower is a TORO 7210.

Start fuse defection. Why ?