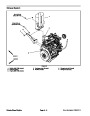

High Temperature Warning Switch

The high temperature warning switch is attached to the

water pump housing on the engine and has a yellow wire

attached to it (Fig. 27). This switch is normally open and

closes when engine coolant temperature reaches

approximately 220oF (105oC).

4. Check resistance of the warning switch with a multi-

meter (ohms setting) as the temperature increases. The

high temperature warning switch is normally open and

should close from 216o to 226oF (102o to 108oC).

5. After testing, install warning switch to the engine

housing.

When engine coolant temperature rises to approximate-

ly 220oF (105oC), the high temperature warning switch

A. Clean threads of housing and switch thoroughly.

Apply thread sealant to the threads of the switch.

closes. The closed switch causes the High Temperature

Warning Light on the console to illuminate and also pro-

vides an input to the Standard Control Module (SCM).

This input causes the SCM high temperature warning

LED to illuminate and the cutting deck (or implement) to

shut down. The temperature warning switch and circuit

wiring should be tested as a SCM input before perform-

ing the following testing procedure.

B. Thread warning switch into the housing. Torque

switch from 16 to 20 ft–lb (21.7 to 27.1 N–m).

C. Reconnect harness wire connector to warning

switch.

6.

7.

Fill engine cooling system.

Lower and secure hood.

Testing

1.

Park machine on a level surface, lower cutting deck

(or implement), stop engine, apply parking brake and re-

move key from ignition switch. Open hood to gain ac-

cess to engine.

1

CAUTION

Make sure engine is cool before removing the

temperature warning switch from engine. Do not

open radiator cap or drain coolant if the radiator

or engine is hot. Pressurized, hot coolant can es-

cape and cause burns.

Figure 27

1.

High temperature warning switch

2.

Lower the coolant level in the engine, remove wire

harness connector from high temperature warning

switch and remove the switch from the engine.

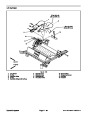

3.

thermometer and slowly heat the oil (Fig. 28).

Put the end of the switch in a container of oil with a

CAUTION

Handle the hot oil with extreme care to prevent

personal injury or fire.

NOTE: Prior to taking resistance readings with a digital

multimeter, short the meter test leads together. The me-

ter will display a small resistance value (usually 0.5

ohms or less). This resistance is due to the internal re-

sistance of the meter and test leads. Subtract this value

from from the measured value of the component you are

testing.

Figure 28

Electrical System

Page 5 – 22

Groundsmaster 7200/7210

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 7200, Toro Groundsmaster 7210 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)

My mower is a TORO 7210.

Start fuse defection. Why ?