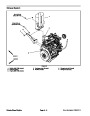

Removal (Fig. 29)

Remove operator seat from machine (see Operator

5. Position seat frame to suspension base.

1.

6. Align bearing blocks on frame with receivers on sus-

pension base and guide frame into place. Insert two (2)

bearing shafts and split nylon bushings to suspension

base and frame. Secure bearing shafts with two (2) roll

pins.

Seat Removal in this section).

2.

Remove armrest assemblies and then back panel

from back of seat.

3.

Remove nut and knob from seat frame.

Carefully peel label from back rest knob (Fig. 30).

7.

of suspension base. Insert cable ends in spring saddle

slots.

Position cables under the seat frame bars and on top

4.

Remove six (6) x–mas tree clips that secure back

cushion to seat frame. Remove back cushion.

8.

Pass weight adjustment knob shaft through weight

indicator, washer and seat frame hole. Thread knob

shaft into weight adjust bar. Install hex nut on knob shaft.

5.

cushion to seat frame. Remove bottom cushion.

Remove two (2) cap screws that secure bottom

9.

eighteen (18) x–mas tree clips.

Position seat boot to seat frame and secure with

6.

Remove hex nut that secures weight adjustment

knob to weight adjust bar. Remove adjustment knob

from weight adjust bar to remove cable tension. Re-

move cables from spring saddle.

10.Position

with two (2) cap screws.

bottom cushion to seat frame and secure

7.

frame to separate seat boot from frame.

Remove eighteen (18) x–mas tree clips from seat

11.

six (6) x–mas tree clips.

Position back cushion to seat frame and secure with

8.

to seat frame. Remove bearing shafts and split nylon

bushings from frame.

Remove two (2) roll pins that secure bearing shafts

12.Assemble

Apply label to knob.

back rest knob to seat and secure with nut.

13.Assemble

to seat.

back panel and then armrest assemblies

9.

Lift seat frame from suspension base.

nut and bolt that secure top of shock ab-

10.Remove

sorber to suspension base.

14.Install

operator seat on machine (see Operator Seat

Installation in this section).

11.

Slide spring saddle from spring arm while disengag-

ing springs at top of suspension base.

12.Remove

springs from spring saddle. Pay close

attention to orientation of springs and spring saddle for

assembly purposes.

13.Remove

nut and bolt that secure bottom of shock ab-

sorber to spring saddle. Remove shock absorber.

Installation (Fig. 29)

1.

Secure bottom of shock absorber to spring saddle

with nut and bolt.

2.

Attach springs to spring saddle in the same orienta-

tion noted during removal.

1

2

3

4

3.

Position spring saddle on spring arm and slide down.

Hook spring ends on top of suspension base.

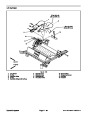

Figure 30

1.

2.

Back rest knob

Seat suspension knob

3.

4.

Lumbar support knob

Seat position lever

4.

Using the suspension base as a pry point, place a

prybar on the top of the spring saddle and push saddle

down to elongate springs enough to allow installation of

the bolt to the top of shock absorber and suspension

base. Secure bolt in position with nut.

Groundsmaster 7200/7210

Page 6 – 27

Chassis

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 7200, Toro Groundsmaster 7210 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)

My mower is a TORO 7210.

Start fuse defection. Why ?