7.

lower bearing cone from frame.

Pry seal from carrier frame. Discard seal. Remove

NOTE: Periodic greasing of castor fork bearing area is

not necessary. Do not replace plug (item 12) with grease

fitting. Grease cap (item 1) will loosen if castor fork has

excessive grease installed.

8.

damage. If bearing cups are damaged, remove bearing

cups from frame and replace.

Inspect bearing cups in carrier frame for wear or

7. Install new grease cap (item 1) so cap shoulder is

flush with top of carrier frame. There should be no evi-

dence that the cap is indented by top of castor fork.

9.

If necessary, remove spacers, seals and bearings

from castor wheel using Figure 15 as a guide. Inspect

and replace all wheel components that show signs of

wear or damage.

8. Position castor wheel to castor fork and secure with

cap screw and lock nut.

Assembly (Fig. 13)

9. Lower machine to ground.

1.

If components were removed from castor wheel, as-

semble castor wheel (Fig. 15):

1

A. Press bearing cups into castor wheel until they

are flush with shoulder in wheel.

B. Install grease packed bearing cone into wheel.

C. Install seals into wheel.

2

D. Carefully fit bearing spacers and then castor

spacer into wheel.

3

2.

press new cups into carrier frame until they are flush with

shoulder in frame.

If bearing cups were removed from carrier frame,

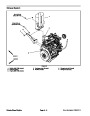

Figure 14

1.

2.

Lock nut

Belleville washer

3.

Upper bearing cone

3.

Pack both bearing cones with new grease. Place

grease packed bearing cone into lower bearing cup of

carrier frame. Install new seal.

2

3

5

4.

Slide castor fork up through carrier frame taking care

to not damage seal. Position grease packed bearing

cone onto castor fork. Place three (3) belleville washers

onto castor fork noting orientation shown in Figure 14.

3

2

1

6

1

IMPORTANT: After correctly tightening the lock nut

that secures castor fork to carrier frame, it should

take from 70 to 80 in–lb (7.9 to 9.0 N–m) to rotate the

castor fork.

4

4

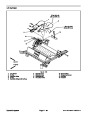

Figure 15

4.

5.

6.

5.

castor fork requires from 70 to 80 in–lb (7.9 to 9.0 N–m)

to rotate.

Install lock nut onto castor fork. Tighten lock nut until

1.

2.

3.

Bearing spacer

Seal

Bearing cone

Bearing cup

Castor wheel

Castor spacer

6.

Remove plug (item 12) from carrier frame. Using

grease gun through plug hole in frame, fill area sur-

rounding the castor fork shaft with grease. Allow grease

to fill cavities below lower bearing, between bearings

and above upper bearing. Reinstall plug into frame.

Groundsmaster 7200/7210

Page 6 – 15

Chassis

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 7200, Toro Groundsmaster 7210 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)

My mower is a TORO 7210.

Start fuse defection. Why ?