Hydraulic Hose and Tube Installation (O–Ring Face Seal Fitting)

1.

tube and the fitting are free of burrs, nicks, scratches or

any foreign material.

Make sure threads and sealing surfaces of the hose/

C. Use a second wrench to tighten the nut to the cor-

rect Flats From Wrench Resistance (F.F.W.R.). The

markings on the nut and fitting body will verify that the

connection has been properly tightened.

2.

As a preventative measure against leakage, it is rec-

ommended that the face seal O–ring be replaced any

time the connection is opened. Make sure the O–ring is

installed and properly seated in the fitting groove. Lightly

lubricate the O–ring with clean hydraulic oil.

Size

F.F.W.R.

4

6

8

(1/4 in. nominal hose or tubing)

(3/8 in.)

(1/2 in.)

(5/8 in.)

(3/4 in.)

(1 in.)

1/2 to 3/4

1/2 to 3/4

1/2 to 3/4

1/2 to 3/4

1/3 to 1/2

1/3 to 1/2

10

12

16

3.

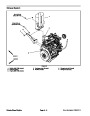

Place the hose/tube against the fitting body so that

the flat face of the hose/tube sleeve fully contacts the O–

ring in the fitting.

Swivel Nut

Fitting Body

O–ring

4.

Thread the swivel nut onto the fitting by hand. While

holding the hose/tube with a wrench, use a torque

wrench to tighten the swivel nut to the recommended

installation torque shown in Figure 3. This tightening

process will require the use of an offset wrench (e.g.

crowfoot wrench). Use of an offset wrench will affect

torque wrench calibration due to the effective length

change of the torque wrench. Tightening torque when

using a torque wrench with an offset wrench will be lower

than the listed installation torque (see Using a Torque

Wrench with an Offset Wrench in the Torque Specifica-

tions section of Chapter 2 – Product Records and Main-

tenance).

Tube or Hose

Figure 1

5.

If a torque wrench is not available or if space at the

swivel nut prevents use of a torque wrench, an alternate

method of assembly is the Flats From Wrench Resist-

ance (F.F.W.R.) method (Fig. 2).

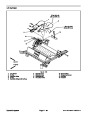

Mark Nut

and Fitting

Body

Final

Position

A. Using a wrench, tighten the swivel nut onto the fit-

ting until light wrench resistance is reached (approxi-

mately 30 in–lb).

Initial

Position

Extend Line

AT WRENCH RESISTANCE

AFTER TIGHTENING

B. Mark the swivel nut and fitting body. Hold the

hose/tube with a wrench to prevent it from turning.

Figure 2

Fitting Dash Size

Hose/Tube Side Thread Size

9/16 – 18

Installation Torque

4

6

18 to 22 ft–lb (25 to 29 N–m)

27 to 33 ft–lb (37 to 44 N–m)

37 to 47 ft–lb (51 to 63 N–m)

60 to 74 ft–lb (82 to 100 N–m)

85 to 105 ft–lb (116 to 142 N–m)

110 to 136 ft–lb (150 to 184 N–m)

140 to 172 ft–lb (190 to 233 N–m)

11/16 – 16

8

13/16 – 16

10

12

16

20

1 – 14

1 3/16 – 12

1 7/16 – 12

1 11/16 – 12

Figure 3

Page 4 – 4

Hydraulic System

Groundsmaster 7200/7210

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 7200, Toro Groundsmaster 7210 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)

My mower is a TORO 7210.

Start fuse defection. Why ?