IMPORTANT: If wheel hub removal is necessary, do

not hit wheel hub or hub puller with a hammer dur-

ing removal. Hammering may cause damage to the

hydraulic wheel motor or wheel hub.

3

35

to 40 ft–lb

to 54 N–m)

(48

1

8.

If necessary, use wheel hub puller to loosen wheel

hub from the wheel motor shaft. Remove loosened lock

nut and wheel hub from wheel motor. Remove woodruff

key from the shaft.

2

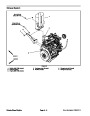

Installation (Fig. 4)

1.

If wheel hub was removed:

4

A. Make sure that wheel hub and wheel motor shaft

are cleaned thoroughly.

Loctite #271

B. Install key to the slot on the wheel motor shaft.

Slide wheel hub onto the shaft.

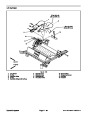

Figure 5

1.

2.

Parking brake assembly

Lock nut

3.

4.

Brake support

C. Secure wheel hub to the motor shaft with lock nut.

Place two (2) hardened washers on brake mounting

Hardened washer

2.

3

screws (Figs. 5 and 6).

4

IMPORTANT: When installing brake to brake sup-

port, take care to not get Loctite on brake pad sur-

face.

2

3.

mounting screws. Secure parking brake to brake sup-

Apply Loctite #271 (or equivalent) to threads of brake

port with two (2) lock nuts. Torque lock nuts from 35 to

5

40

ft–lb (48 to 54 N–m).

1

4.

Place brake support (with parking brake assembly

attached) to wheel hub disc and frame making sure that

disc is between the two (2) stators (brake pads) in the

brake assembly.

Figure 6

1.

2.

3.

Wheel hub

Parking brake assembly

Lock nut

4.

5.

Brake support

Hardened washer

5.

ing holes of brake support and frame but do not fully

tighten.

Place four (4) cap screws and flange nuts in mount-

6.

ance between the wheel hub disc and both springs in the

Adjust position of brake support so that the clear-

1

parking brake (Fig. 7) is from 0.030” to 0.070” (0.8 to

1.7

mm). When clearance is correct, fully tighten fasten-

ers.

2

7.

Attach brake rod assembly to parking brake lever

with flat washer and retaining ring.

8.

9.

Secure wheel to machine with five (5) lug nuts.

Lower wheel to ground. Torque wheel lug nuts in a

5

4

crossing pattern from 75 to 85 ft–lb (102 to 115 N–m).

3

10.If

torque lock nut (item 6) from 300 to 400 ft–lb (407 to 542

N–m). Release parking brake.

wheel hub was removed, apply parking brake and

Figure 7

4.

5.

1.

2.

3.

Brake swivel

Caliper brake lever

Wheel hub disc

Hardened washer

Clearance

11.

Check parking brake and brake switch operation.

Groundsmaster 7200/7210

Page 6 – 9

Chassis

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 7200, Toro Groundsmaster 7210 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)

My mower is a TORO 7210.

Start fuse defection. Why ?