8.

fittings to prevent system contamination.

Put clean plugs in disconnected hydraulic hoses and

8. Fill hydraulic tank with new hydraulic fluid.

Install operator seat and seat base (see Operator

9.

9.

port that retain hydraulic tank to frame.

Remove two (2) washer head screws and tank sup-

Seat Installation in the Service and Repair section of

Chapter 6 – Chassis).

10.Remove

hydraulic tank toward front of machine.

10.Operate machine. Check hydraulic oil level and ad-

just if necessary. Check hydraulic components for leaks.

Tighten any loose connections.

11.

Inspect foam strips under hydraulic tank. Replace

strips if damaged.

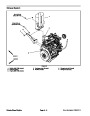

12.As

needed, remove fittings from hydraulic tank using

Figure 29 as a guide. Discard and replace any removed

O–rings.

RIGHT

Hydraulic Tank Inspection (Fig. 29)

FRONT

1.

Clean hydraulic tank and suction strainer with sol-

vent.

3

2.

Inspect hydraulic tank for leaks, cracks or other dam-

age.

1

Hydraulic Tank Installation (Fig. 29)

1.

If suction strainer was removed from hydraulic tank,

place new, lubricated O–ring on strainer. Thread strain-

er into tank and torque from 60 to 66 ft–lb (82 to 90

N–m).

2.

Attach removed fittings with new, lubricated O–rings

to hydraulic tank using Figure 29 as a guide (see Hy-

draulic Fitting Installation in the General Information

section of this chapter). Tighten fittings to torque values

identified in Figure 29.

2

4

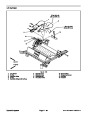

Figure 30

1.

2.

Screw (3 used)

Front cover

3.

4.

Frame

Foam strip (3 used)

3.

frame with tank support and two (2) washer head

screws.

Position hydraulic tank to machine. Secure tank to

2

4.

and fittings during the removal procedure.

Remove plugs that were installed to hydraulic hoses

5.

Attach hydraulic hoses to fittings on hydraulic tank

using labels placed during removal (see Hydraulic Hose

and Tube Installation in the General Information section

of this chapter).

3

FRONT

6.

Install brake handle to machine (see Parking Brake

Assembly in the Service and Repairs section of Chapter

– Chassis). Make sure that parking brake switch op-

eration is correct after brake handle is installed.

1

6

Figure 31

3.

1.

2.

Hydraulic tank

Transmission

Gear pump

7.

Secure front cover to machine (Fig. 30).

Groundsmaster 7200/7210

Page 4 – 47

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 7200, Toro Groundsmaster 7210 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)

My mower is a TORO 7210.

Start fuse defection. Why ?