4.

Remove wheel assembly and brake assembly from

4. Remove plugs from disconnected hydraulic hoses

and wheel motor ports.

the machine (see Wheel Removal and Brake Removal

in the Service and Repairs section of Chapter 6 – Chas-

sis).

5.

Lubricate and install new O–rings to hydraulic fit-

tings. Install fittings into wheel motor ports (see Hydrau-

lic Fitting Installation in the General Information section

of this chapter). Make sure that fittings are orientated

correctly.

IMPORTANT: DO NOT hit wheel hub, wheel hub

puller or wheel motor with a hammer during removal

or installation. Hammering may cause damage to

the wheel motor.

6.

Using labels placed during the removal process,

5.

wheel motor.

Use appropriate puller to loosen wheel hub from

properly connect hydraulic hoses to wheel motor fittings

(see Hydraulic Hose and Tube Installation in the Gener-

al Information section of this chapter).

6.

Remove lock nut and loosened wheel hub from mo-

tor shaft. Locate and retrieve woodruff key from wheel

motor shaft.

7. Make sure that tapers of wheel motor shaft and

wheel hub are thoroughly clean.

7.

Thoroughly clean hydraulic hose ends and fittings on

8. Position woodruff key to keyslot in wheel motor shaft.

wheel motor to prevent hydraulic system contamination.

9.

Place wheel hub on motor shaft and secure with lock

8.

Label all hydraulic hoses and fittings for assembly

nut.

purposes (Fig. 33). Remove hydraulic hoses from fit-

tings on wheel motor. Allow hoses to drain into a suitable

container.

10.Install

brake assembly and wheel assembly to the

machine. Make sure that proper clearance exists be-

tween brake assembly and wheel hub rotor (see Wheel

Installation and Brake Installation in the Service and Re-

pairs section of Chapter 6 – Chassis).

9.

sembly. Remove hydraulic fittings from wheel motor.

Remove and discard O–rings from fittings.

Mark hydraulic fitting orientation to allow correct as-

11.

Lower the machine to the ground.

lock nut (item 1) from 300 to 400 ft–lb (407

10.Put

clean plugs in disconnected hydraulic hoses and

12.Torque

wheel motor ports to prevent system contamination.

to 502 N–m).

11.

ing removal.

Support the wheel motor to prevent it from falling dur-

13.Make

essary.

sure hydraulic tank is full. Add correct oil if nec-

12.Remove

four (4) socket head screws that secure

wheel motor to the machine.

2

13.Remove

wheel motor from frame.

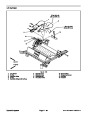

Installation (Fig. 32)

IMPORTANT: Because of internal differences in

wheel motors, DO NOT interchange wheel motors

on machine (i.e. do not put RH motor on left side of

machine). If necessary, use parts catalog and part

number on wheel motor to identify RH and LH mo-

tors.

4

3

FRONT

1

1.

in wheel motor are facing up.

Position wheel motor to frame. Make sure that ports

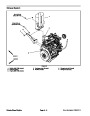

Figure 33

3.

4.

1.

2.

Hydraulic tank

Transmission

RH wheel motor

LH wheel motor

2.

3.

Clean threads in frame and on socket head screws.

Apply Loctite #271 (or equivalent) to threads of sock-

et head screws. Secure wheel motor to frame with four

(4)

socket head screws.

Groundsmaster 7200/7210

Page 4 – 49

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 7200, Toro Groundsmaster 7210 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)

My mower is a TORO 7210.

Start fuse defection. Why ?