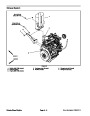

Figure 39 (continued)

1.

Solenoid assembly

Solenoid valve assembly

Bolt (3 used)

27. Seal (4 used)

53. Valve plate (2 used)

54. Cylinder block assembly (2 used)

55. Thrust plate (2 used)

56. Swash plate (2 used)

57. Pin (4 used)

2.

28. O–ring (2 used)

3.

29. Washer (2 used)

4.

Bolt (2 used)

30. Bearing (5 used)

5.

Hex plug (2 used)

O–ring

31. Bearing (2 used)

6.

32. Side cover (2 used)

33. Socket head screw (3 used per cover)

34. Nut (2 used)

58. Gasket

7.

Pump body

59. Pump housing

60. PTO brake assembly

61. Push rod (3 used)

62. PTO shaft

63. Seal ring (4 used)

64. RH pump shaft

65. LH pump shaft

66. Pump gear (2 used)

67. Gasket

8.

Pin (2 used)

9.

O–ring

35. Control arm (2 used)

36. Socket head screw (2 used)

37. Bearing (3 used)

38. O–ring (2 used)

39. Socket head plug (2 used)

40. O–ring (8 used)

41. Hex plug (8 used)

42. Pipe assembly

43. Seal (2 used)

44. Washer (2 used)

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

Charge pump assembly

Key

O–ring (5 used)

Piston

Spring

Collar

Bolt and washer (2 used)

Accumulator cover

Gasket

Filter bypass valve assembly

Hex drain plug

Charge relief valve assembly

Pressure valve assembly

Socket head plug (4 used)

Filter adapter

68. Gear case housing

69. Flange head screw (13 used)

70. Pipe assembly

71. Spacer

45. LH flushing valve

46. Reverse relief valve (2 used)

47. Forward relief valve (2 used)

48. Socket head screw (8 used)

49. RH flushing valve

50. Bypass valve (2 used)

51. Center case

72. Input gear

73. PTO gear

74. Input shaft

75. Retaining ring

76. Clutch assembly

77. O–ring

Oil filter

Retaining ring (4 used)

52. Pin (4 used)

78. Key

IMPORTANT: If a transmission failure occurred, re-

fer to Traction Circuit (Closed Loop) Component

Failure in the General Information section for infor-

mation regarding the importance of removing con-

tamination from the traction circuit.

Transmission Disassembly (Fig. 39)

1.

2.

coil and O–ring from solenoid valve stem. For assembly

purposes, note that “KANZAKI” molded into the coil has

the “I” nearest the nut location as coil direction is impor-

tant for proper solenoid operation.

Thoroughly clean exterior of transmission.

Remove nut, lock washer, washer, O–ring, solenoid

1

2

4

5

3.

pump body.

Remove solenoid valve stem from transmission

3

4.

Remove pin from spool. Remove spool, sleeve and

solenoid valve spring from transmission pump body. For

assembly purposes, note that step in spool is toward

spring location and that sleeve is installed so that holes

are closest to the spring location as well.

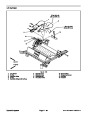

Figure 40

1.

2.

3.

Solenoid coil

Solenoid valve stem

Pin

4.

5.

Spool

Sleeve

Groundsmaster 7200/7210

Page 4 – 57

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 7200, Toro Groundsmaster 7210 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)

My mower is a TORO 7210.

Start fuse defection. Why ?