4.

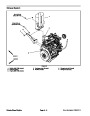

Figures 21 and 23 as guides.

Remove lift arm components as necessary using

4

1

2

3

5

NOTE: If pull link assembly (item 27) removal is neces-

sary, refer to Cutting Deck Pull Links in the Service and

Repairs section of Chapter 7 – Cutting Deck.

Assembly (Fig. 21)

1.

damage (Fig. 24). Replace flange bushing(s) if neces-

sary.

Check flange bushing(s) in carrier frame for wear or

2.

ures 21 and 23 as guides.

Install lift arm components as necessary using Fig-

6

Figure 23

4.

5.

6.

A. If rear lift arm was removed from deck lift shaft,

make sure to thoroughly clean tapers of shaft and lift

arm bore before installing lift arm to shaft. Also, when

installing washer (item 26), position washer cavity to-

ward lift arm (Fig. 25).

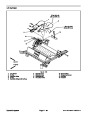

1.

2.

3.

Adjustment clevis

Jam nut

Clevis pin

Ring pin

Flange nut

Cutting deck

B. If ball joints were removed from link (item 13),

install ball joints equally on both ends of link. Adjust

center to center length of link assembly from 18.070”

to 18.180” (45.9 to 46.1 cm) (Fig. 26). Tighten jam

nuts to secure ball joints to link. Make sure that ball

joints stay inline when tightening jam nuts.

2

NOTE: Do not change the link assembly length to

adjust the height–of–cut or for any other reason.

1

NOTE: When properly installed, flange nuts (item

3

23)

should have flange surface against lift arm and

not against chain.

Figure 24

1.

2.

Carrier frame

3.

Flange bushing (2 used)

C. If cap screw (item 20) was removed from chain

(item 22), insert screw into upper link of chain and

thread flange nut (item 23) onto screw with flange

away from link. Torque flange nut to 50 ft–lb (67

N–m). When fastening chain to front lift arm, torque

second flange nut to 50 ft–lb (67 N–m). When instal-

ling chain to rear lift arm, torque cap screw to 50 ft–lb

Flange bushing (2 used)

2

1

3

(67

N–m).

3.

4.

Lubricate all lift arm grease fittings after assembly.

4

Start engine and fully raise cutting deck. Stop engine

Figure 25

and remove key from the ignition switch. Install HOC pin

into HOC bracket to allow desired height–of–cut (Fig.

22).

1.

2.

Rear lift arm

Washer

3.

4.

Washer cavity

Deck lift shaft

18.070

(45.9

to 18.180 in

to 46.1 cm)

Figure 26

Groundsmaster 7200/7210

Page 6 – 23

Chassis

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 7200, Toro Groundsmaster 7210 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)

My mower is a TORO 7210.

Start fuse defection. Why ?