10.Remove

necessary, remove gear pump from transmission (see

Gear Pump Removal in this section).

oil filter from transmission. Discard filter. If

14.On both sides of transmission, remove retaining ring

that secures pump control rod end onto transmission

control arm (Fig. 36). Slide control rod from control arm.

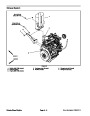

NOTE: Two (2) 8 mm eyebolts can be installed into

threaded bosses in top of transmission to allow use of

a lift or hoist to remove transmission (Fig. 37).

15.If hydraulic fittings are to be removed from transmis-

sion, mark fitting orientation to allow correct assembly.

Remove hydraulic fittings from transmission as needed.

Discard fitting O–rings.

CAUTION

16.Inspect flywheel housing and coupler on engine fly-

wheel for evidence of wear or damage.

Support transmission assembly when removing

it from the flywheel housing to prevent it from fal-

ling and causing personal injury.

Transmission Installation (Fig. 35)

1. Make sure that flywheel coupler and flywheel hous-

ing are secure on engine (see Engine Installation in the

Service and Repairs section of Chapter 3 – Kubota Die-

sel Engine).

11.

Remove seven (7) cap screws and lock washers that

secure the transmission to the flywheel housing. Note

location of the shorter cap screw for assembly pur-

poses.

2.

If hydraulic fittings were removed from transmission,

lubricate and install new O–rings to fittings. Install fit-

tings into transmission ports (see Hydraulic Fitting

Installation in the General Information section of this

chapter). Tighten fittings to torque values identified in

Figure 38).

IMPORTANT: Make sure to not damage the trans-

mission, flywheel housing, hydraulic lines, electri-

harness or other parts while removing

transmission.

cal

3.

gear pump (see Gear Pump Installation in this section).

If gear pump was removed from transmission, install

12.Move

machine and away from the flywheel housing and cou-

pler on engine flywheel. Lift transmission from machine.

transmission assembly toward the front of the

4.

Slide both pump control rods onto transmission con-

trol arms and secure with retaining rings (Fig. 36).

13.Locate

and note location of two (2) dowel pins from

transmission and flywheel housing.

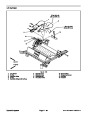

58 to 72 ft–lb

(79 to 97 N–m)

60

(82

to 74 ft–lb

to 100 N–m)

60

to 74 ft–lb

35 to 43 ft–lb

(48 to 58 N–m)

(82

to 100 N–m)

9

to 11 ft–lb

(

13 to 15 N–m)

81 to 99 ft–lb

(110 to 134 N–m)

35 to 43 ft–lb

(48 to 58 N–m)

58 to 72 ft–lb

(79 to 97 N–m)

20 to 26 ft–lb

(28 to 35 N–m)

Figure 38

Hydraulic System

Page 4 – 54

Groundsmaster 7200/7210

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 7200, Toro Groundsmaster 7210 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)

My mower is a TORO 7210.

Start fuse defection. Why ?