ProcedureforTractionCircuitChargePressureTest

Make sure hydraulic oil is at normal operating tem-

perature by operating the machine for approximately 10

minutes. Make sure the hydraulic tank is full.

8. Also, with the pressure gauge still connected to the

charge pressure test port, take a gauge reading while

operating the machine in forward and reverse. Start the

engine, release parking brake and put throttle at full en-

gine speed (2750 RPM). Push the traction pedal for-

ward, then reverse.

1.

2.

Park machine on a level surface with the cutting

decks lowered and off. Make sure engine is off and the

parking brake is applied.

GAUGE READING TO BE 315 to 345 PSI (21.8 to

23.7

bar).

9.

Ifcharge pressure isgood under no load(step 5),but

CAUTION

drops below specification when under traction load

(step 8), the piston (traction) pump and/or wheel mo-

tor(s) should be suspected of wear and inefficiency.

When the pump and/or traction motor(s) are worn or

damaged, the charge pump is not able to keep up with

internal leakage in traction circuit components.

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

10.Disconnect

pressure gauge from test port.

3.

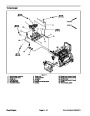

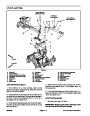

charge pressure test port fitting on hydrostat (Fig. 23).

Connect a 1000 PSI (70 Bar) pressure gauge onto

1

4.

at idle speed. Check for hydraulic leakage and correct

before proceeding with test.

After installing pressure gauge, start engine and run

2

5.

Operate the engine at full engine speed (2750 RPM)

with no load on the hydraulic system.

GAUGE READING TO BE 315 to 345 PSI (21.8 to

23.7

bar).

6.

7.

Stop engine and record test results.

If there is no pressure, or pressure is low, check the

following items:

Figure 23

A. Restriction in gear pump intake line or reservoir

strainer.

1.

Hydrostat port G

2.

Charge relief valve

B. Inspect charge pressure relief valve located in

the hydrostat (Fig. 23). The charge pressure relief

valve is adjusted with shims. If charge pressure is

low, shim(s) can be added between relief valve cap

andspring.Ifchargepressureishigh,shim(s) canbe

removed from between relief valve cap and spring.

C. Consider a leaking check/relief valve in the hy-

drostat.

D. Leakage in the traction control manifold, the

mow/transport manifold and/or the steering/cooling

fan manifold will affect charge circuit pressure. Con-

sider that damaged cartridge seals in these man-

ifolds will cause low charge circuit pressure.

E. If necessary, check for internal damage or worn

parts in gear pump (P3). A worn or damaged gear

pump(P3)willalsoaffectdecklift/lower,steeringand

engine cooling fan operation.

Groundsmaster 5900/5910

Page 4 -- 41

Hydraulic System

Product Specification

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 5900, Toro Groundsmaster 5910 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |